With intermittent motion, facial-mask cartoner ZHJ-100B through multiple servo feeding is a piece of high-tech equipment integrating photoelectric, pneumatic and mechanic features, applicable to packing medicine trays, facial masks (linings), drug bottles, cosmetics and other similar products into cartons. Stable and reliable process allows easy replacing and adjusting of different sizes of cartons, automatic leaflet folding, carton erecting, loading of products and leaflets, batch mark embossing, as well as carton sealing and discharging. A chain of autonomous protective devices ensures safe and effective operation. The machine can be integrated with tray making and loading machine, facial mask packing machine, filling machine, weight checker, cellophane overwrapping machine (stretch bander), case packer and other end-of-line packaging equipment to constitute a complete packaging line.

Item NO.:

ZHJ-100BPayment:

T/T; L/C; WESTERN UNIONMarket Price:

$20000Price:

$20000Product Origin:

CHINAColor:

WHITE+SILVERShipping Port:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOULead Time:

15-30DAYSWeight:

2500KG

Fully-automatic Facial Mask Cartoner ZHJ-100B

Description

With intermittent motion, facial-mask cartoner ZHJ-100B through multiple servo feeding is a piece of high-tech equipment integrating photoelectric, pneumatic and mechanic features, applicable to packing plastic trays, facial masks (linings), cosmetics and other similar products into cartons. Stable and reliable process allows easy replacing and adjusting of different sizes of cartons, automatic leaflet folding, carton erecting, loading of products and leaflets, batch mark embossing, as well as carton sealing and discharging. A chain of autonomous protective devices ensures safe and effective operation. The machine can be integrated with tray making and loading machine, facial mask packing machine, filling machine, weight checker, cellophane overwrapping machine (stretch bander), case packer and other end-of-line packaging equipment to constitute a complete packaging line.

Features

1. Stable operation and reliable process makes changing and adjusting different sizes of cartons easy, featuring automatic leaflet folding, carton forming, loading products and leaflets, batch mark embossing, and carton sealing and discharging.

2. With upper and lower feedings. No leaflet nor carton is delivered for missed blister. Empty running is possible. With metal detection and rejection, empty cartons will be rejected.

3. Roller-type steel alphabet dies for batch mark embossing, 3 rows typesetting, clear fonts and easy to install alphabet dies.

4. Double suction heads pick and place cartons. The magazine can hoard 500-800 cardboard blanks. Cartons are transported by conveyor belt which is controlled by replenishing pneumatic cylinder.

5. With overloading monitoring, empty cartons will be rejected and fault messages will be displayed when overload happens.

Equipment Display

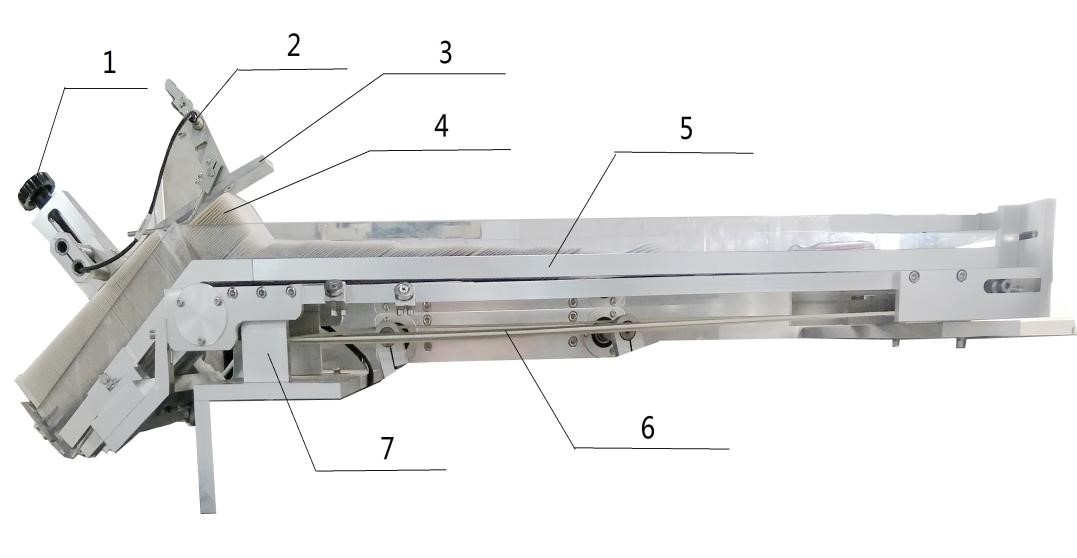

Carton loading mechanism

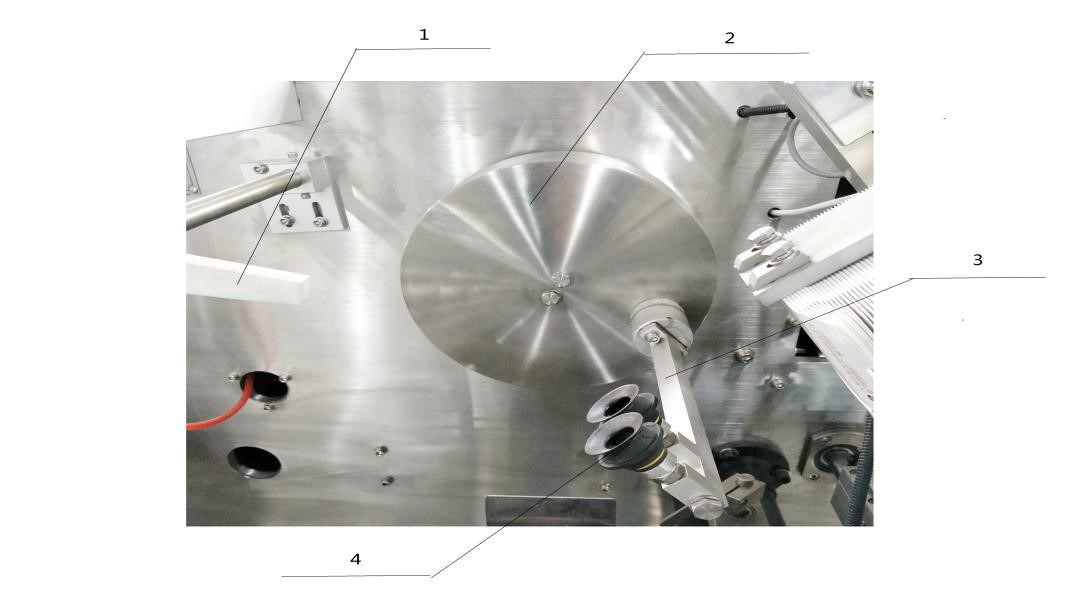

Carton sucking mechanism

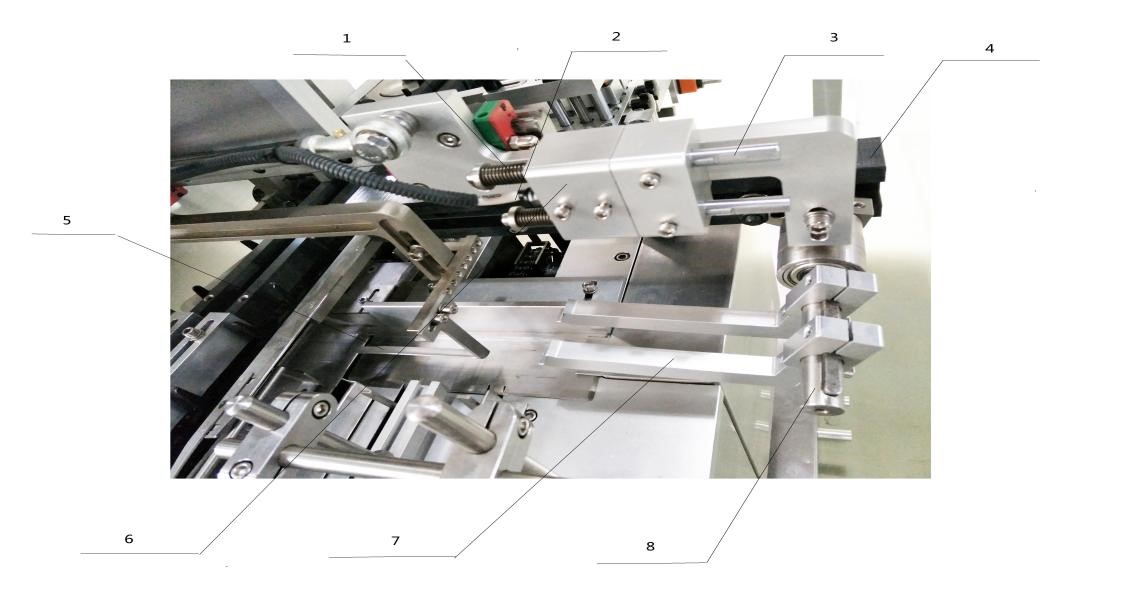

Carton pushing mechanism

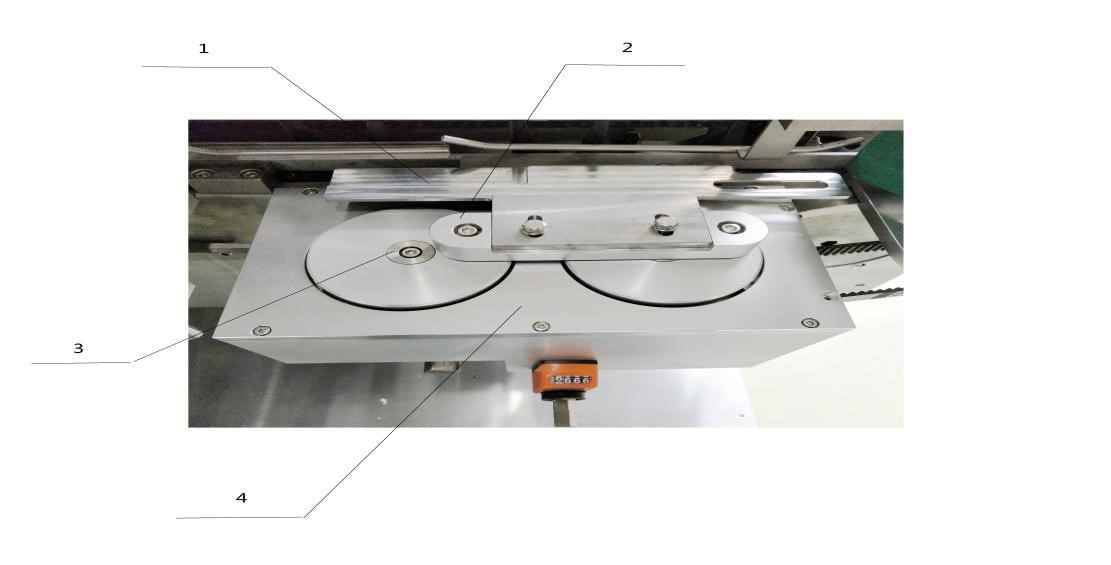

Tuck in locking

Parameters

Parameters

|

Design max. production capacity |

100 cartons/minute |

|

Carton size (LxWxH) |

Max. 210x130x40mm |

|

Min. 155x100x25mm |

|

|

Lining paper size (LxW) |

Max. 290x210mm |

|

Min. 110x110mm |

|

|

Main motor power |

2.2Kw |

|

Total power |

3.8Kw |

|

Air consumption |

0.6-0.9m3/minute |

|

Weight |

2500Kg |

|

Dimensions (LxWxH) |

5500x1350x1700mm |