Item NO.:

Lotion Cellophane Wrapping and Case Packing Production LinePayment:

T/T; L/C; WESTERN UNIONProduct Origin:

ChinaColor:

White, SilverShipping Port:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOULead Time:

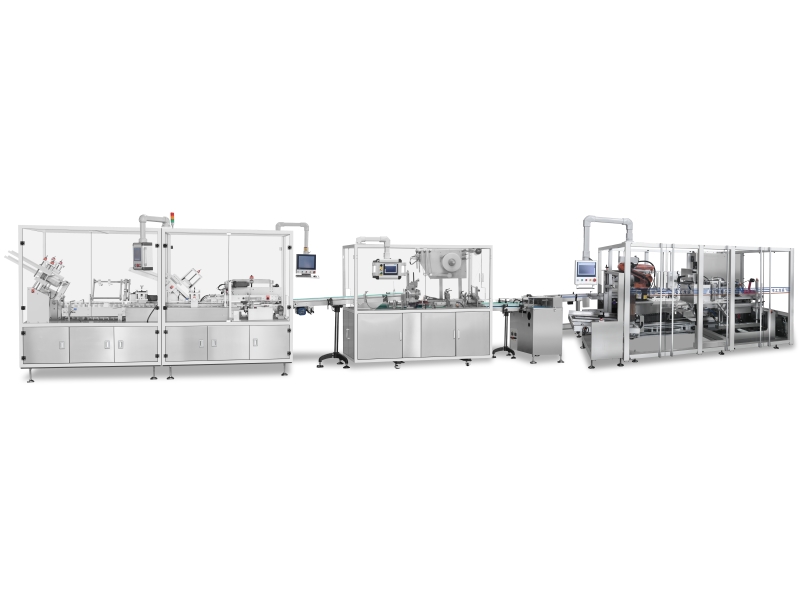

80 DAYSTPZX-100L Lotion Cellophane Wrapping and Case Packing Production Line

Parameters

|

Model |

TPZX-100L |

|

|

Cartoner module |

Carton size(LxWxH) |

(80-200)x(30-120)x(25-100)mm |

|

Carton quality |

300-350g/m2 white cardboard |

|

|

Leaflet quality |

60-65g/m2 |

|

|

Output |

40-80 cartons/min |

|

|

Total power |

11KW |

|

|

Dimensions(LxWxH) |

2920x1140x1880mm 5580x1440x1880mm(including lining mechanism) |

|

|

Weight |

1500Kg |

|

|

Cellophane Wrapping module |

Bundle size(LxWxH) |

(50-220)x(30-130)x(20-60)mm |

|

Packaging materials |

BOPP/PVC Thickness:0.018-0.030mm |

|

|

Output |

40-80 cartons/min |

|

|

Power supply |

220V/50Hz 380V/50Hz |

|

|

Power |

3KW |

|

|

Compressed air |

0.6-0.8Mpa |

|

|

Dimensions |

3980x900x1590mm |

|

|

Weight |

800Kg |

|

|

All-in-one Case Packer module |

Case size(LxWxH) |

(300-550)x(200-400)x(200-350) customizable |

|

Robot arm packing speed |

10 placements/min (related to palletizing layers) |

|

|

Power supply |

380V 50Hz |

|

|

Power |

8Kw |

|

|

Compressed air |

0.6Mpa |

|

|

Dimensions |

4400x2300x1860mm(for reference only) |

|

|

Weight |

1200Kg |

|

|

Air pump |

Compressed air |

0.5-0.8Mpa |

|

Flow |

>0.2m2 |

|

|

Motor frequency |

0-50Hz |

|

|

Max. air consumption |

500L/min |

|

|

Certificates |

ISO 9001: 2000; CE |

|

|

Warranty |

1 year |

|

Description

With automatic feeding, wrapping, cellophane folding, heat sealing, counting and tear tape attaching, Cellophane Wrapper is a bottom-sealing cellophane wrapper, widely used in 3D cellophane wrapping of single or multiple cuboid products in pharmaceutical, cosmetic, health care, food and other industries. Stable operation and firm smooth sealing make the products nicely presented, tamper-evident, and moisture-and-dust-proof. The machine will immediately upgrade the wrapped product to a higher class, increasing added value. Integrated with all-in-one case packer, it can achieve intelligent, digital, and net-worked production.

Features

Lotion cartoner module

1.With PLC+HMI, it is equipped with high end servo motors, featuring easy format change,fast speed, stable performance, and accurate position. It is intuitive to operate even by an inexperienced operator.

2.The cartoning speed and accumulated output will be shown on touch screen.Functions can be chosen manually and automatically.

3. Equipped with an automatic detection system, ZHJ-100B automatically detects and locates the shutdown for failures such as lack of materials, materials not in place, and inability to open the carton.

4. Fault alarm and corresponding maintenance methods will be shown on touch screen.

Cellophane wrapper module

This machine has incorporated advanced technologies abroad. With compact structure, it is easy to operate and service, suitable for overwrapping products of various specifications by changing only a few parts. It is applicable to large cuboid products, multiple overlapped products and the products requiring photoelectric tracking, such as packets of cigarettes, boxes of tea, boxes of chewing gum, medicines, cosmetics, and health products.

All-in-one case packer module

1. PLC + HMI controls automatic counting, stacking, case erecting, loading and sealing.

2. The stacking system can be adjusted according to the size of the case and stacking pattern.

3.Not less than 10 placements per minute for quick case loading.

4.Case erector driven by servo and case loader by four-axis Yamaha robot ensure stable and reliable process.

5. Highly compatible. Hand-wheel marked with scales for adjustment and fine-tuning.

6.Warnings are in place for machine fault, missed product, missed case or machine jam.