What Are Industrial Automatic Cartoners and How Do They Optimize Packaging Efficiency?

Release time: 2025-09-29

In today’s competitive manufacturing environment, businesses seek solutions that streamline operations, reduce labor costs, and boost efficiency. One of the most effective tools is the industrial automatic cartoner, a machine that automates product packaging into cartons. This article explores what these machines are, how they work, their types, and the key benefits they offer across industries.

Table of Contents

What is an Industrial Automatic Cartoner?

An industrial automatic cartoner is designed to automate the process of packing products into cartons or boxes. This includes folding, loading, sealing, and labeling cartons, which is essential for industries like food and beverage, pharmaceuticals, and consumer goods. These machines improve packaging speed, accuracy, and consistency while reducing manual labor.

How Do Automatic Cartoners Work?

Automatic cartoners operate through integrated stages to minimize human input while maximizing speed and precision:

1. Product Feeding and Orientation

Products are loaded onto conveyors and oriented correctly to prevent damage during packaging.

2. Carton Forming and Folding

Pre-folded cartons are shaped into boxes by the machine, ensuring uniform and secure cartons.

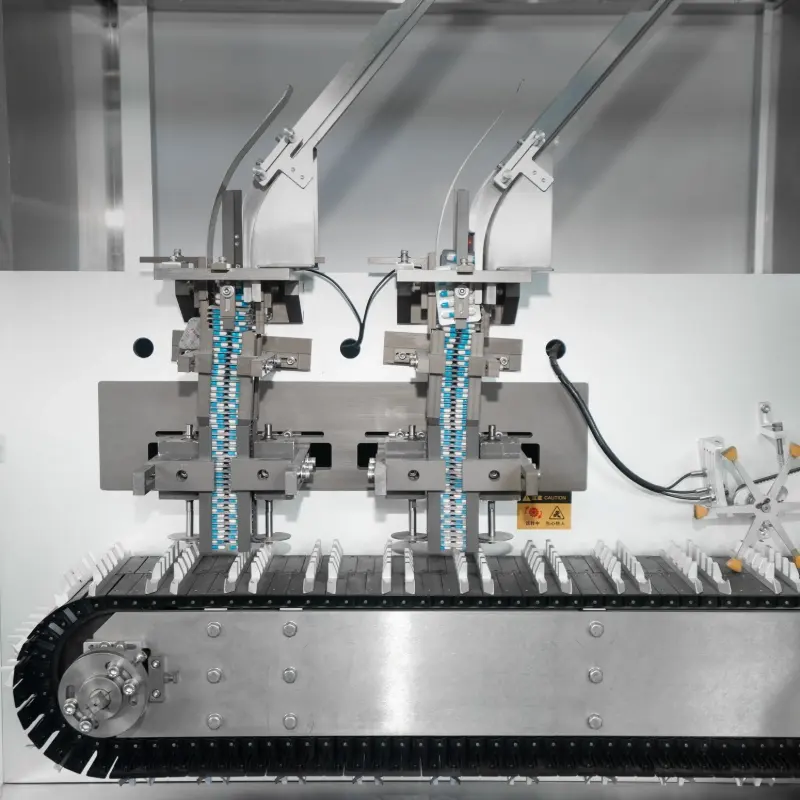

3. Product Loading

Mechanical arms or conveyors load products into the cartons efficiently and safely.

4. Sealing and Labeling

Cartons are sealed via glue, tape, or heat sealing, with some systems automatically labeling products with barcodes, safety information, or branding.

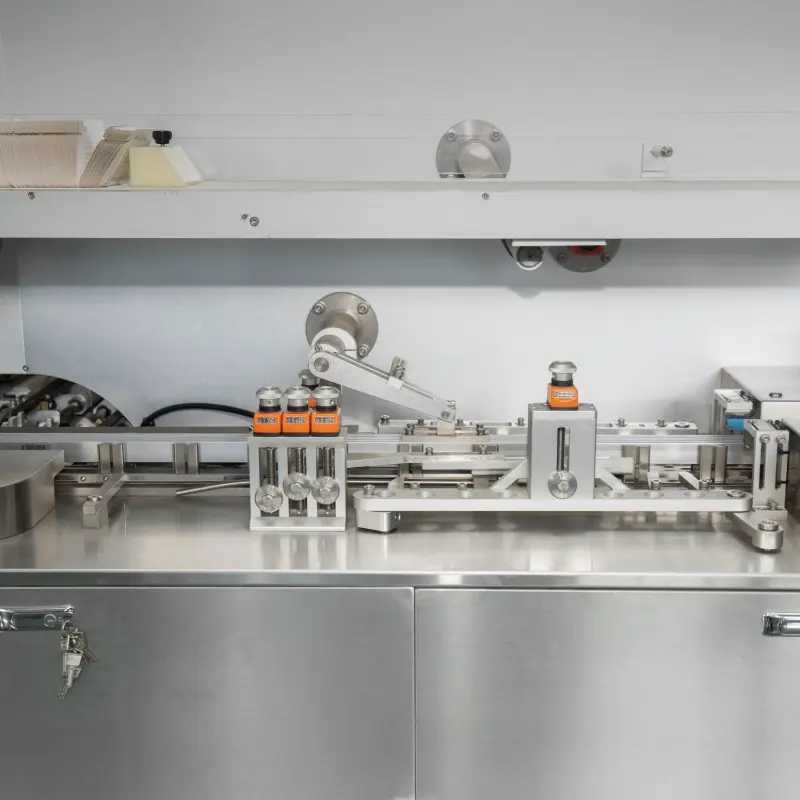

5. Final Inspection

Built-in cameras or sensors verify that each carton is correctly formed, loaded, and sealed before shipment.

Types of Industrial Automatic Cartoners

Horizontal Automatic Cartoners

- Ideal for bottles, cans, and products loaded on their sides.

- Advantages: High-speed operation, suitable for large-scale production, versatile with product sizes.

Vertical Automatic Cartoners

- Suited for smaller or upright products like pouches and sachets.

- Advantages: Compact design, space-saving, highly flexible for varying carton sizes.

Benefits of Using Industrial Automatic Cartoners

1. Increased Packaging Speed and Efficiency

Machines operate continuously at high speeds, reducing production bottlenecks.

2. Reduced Labor Costs

Automation decreases reliance on manual labor, saving costs and freeing employees for higher-value tasks.

3. Improved Packaging Consistency and Accuracy

Ensures precise carton formation, loading, and sealing, minimizing product damage.

4. Enhanced Product Protection

Secure cartons reduce crushing or misalignment, ensuring product safety.

5. Better Use of Floor Space

Vertical and compact designs optimize facility layout.

6. Flexibility and Scalability

Adjustable settings accommodate different carton sizes, product shapes, and production changes.

Industries That Benefit from Industrial Automatic Cartoners

1. Food and Beverage

Used for frozen foods, drinks, snacks, and ready-to-eat meals requiring fast, hygienic packaging.

2. Pharmaceuticals

Ensures safe, sterile packaging of medications, supplements, and medical devices.

3. Cosmetics and Personal Care

Maintains product protection and brand presentation for skincare, perfumes, and lotions.

4. Consumer Goods

Packaging electronics, household items, and small appliances efficiently and consistently.

Why Invest in an Industrial Automatic Cartoner?

Investing in these machines allows companies to:

- Increase productivity and meet market demand.

- Reduce labor costs and reliance on manual packing.

- Ensure consistent, high-quality packaging.

- Optimize facility floor space.

- Gain operational flexibility for multiple product lines.

Looking to boost your packaging efficiency? Get in touch with us today to explore the best industrial automatic cartoners for your business needs and streamline your packaging operations.