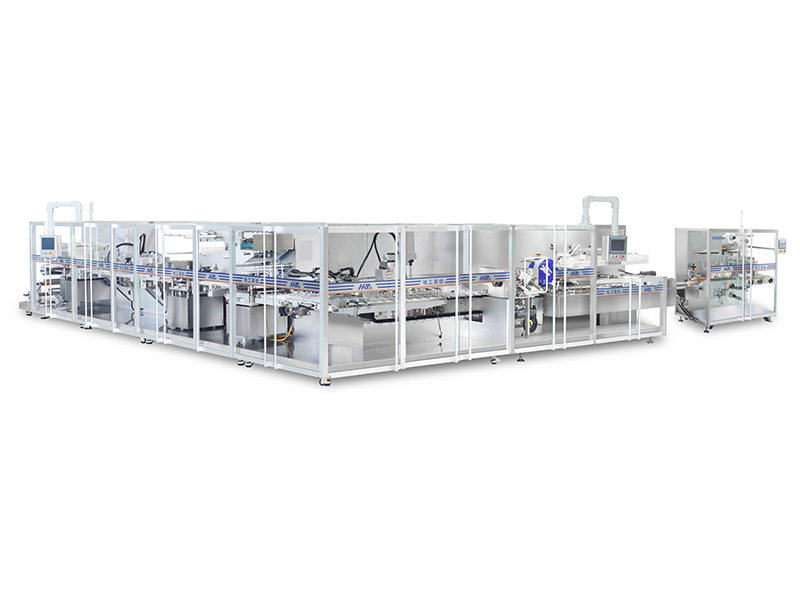

With modular design, DPTL-350/420/600 is applicable to tray making, loading, lamination and packing into cartons for ampoules, injectables (powder), oral liquids or trays of bigger sizes and special shapes for medical appliances, electronics (cells) and cosmetics, all modules integrated in one line with high speed.

Item NO.:

DPTL-350/420/600Order(MOQ):

1Payment:

T/T; l/C; WESTERN UNIONProduct Origin:

CHINAColor:

WHITR+SILVERShipping Port:

SHANGHAI; SHENZHEN; NINGBO; QINGDAO; GUANGZHOULead Time:

15-30DAYSWeight:

600KG 7000KG

Blister Packing and Cartoning Machine DPTL-350/420/600

Features

1. Servo drive for the whole line with intelligent integration and high-speed operation.

2. Tray making, loading, lamination and cartoning take place in one machine. Material infeed by pick-and-place servo manipulator allows accurate placement in the carton magazine.

3. Multiple servo-driven material magazines in the cartoner make it possible to deliver the material accurately on the conveyor belt.

4. Intuitive to operate with back-push structure for cartoning unit and optimized ergonomic design.

5. Easily visible open balcony design of the operation area makes daily cleaning and maintenance easy. Transmission area enclosed in the back of the machine and insulated from the operation area avoids cross contamination.

Parameters

|

Line Model |

DPTL350-150 |

DPTL420-200 |

DPTL600-300 |

|

Max. capacity |

150 cartons/min |

200 cartons/min |

300 cartons/min |

|

Carton size (LxWxH) |

Max. 170x180x60mm |

||

|

|

Min. 55x30x15mm |

||

|

Total power |

16.5Kw |

19.4Kw |

21.4Kw |

|

Main motor power |

1.5Kw |

2.4Kw |

4.4Kw |

|

Pressure |

≥0.6MPa |

≥0.6MPa |

≥0.6MPa |

|

Dimensions (LxWxH) |

10500x1170x1900mm |

11800x1570x2100mm |

12000x1600x2100mm |

|

Weight |

6600Kg |

7000Kg |

7500Kg |