Selection of PVC (aluminum foil) for blister packaging machine and temperature adjustment

Blister packaging machine has been widely acclaimed packaging method for tablets and capsules in recent years.

1. The choice of PVC/PTP (aluminum foil)

First, select the suitable specifications of PVC and PTP according to the blister packaging machine model, and then check whether the thickness and color of PVC and PTP are uniform to ensure that the blown blister is uniform. In addition, when PVC is heated to a certain temperature, the plasticity is suitable, and it is easy to form a blister; PTP has suitable viscosity, the made blister is full and neat, and the aluminum-plastic panel is not easy to open.

2. Adjustment of temperature and air pressure

If the heating temperature is too high, PVC will be too soft and easy to blow the bubble; if the temperature is too low, it is difficult to blow. If the air pressure is too high, it is easy to blow the blister, and if the air pressure is too low, the blister cannot be blown. The actual operating experience shows that the preheating temperature is about 100℃, the blowing process temperature is about 145℃, and the heat sealing temperature should be about 150℃. In addition, the principle of high temperature in winter and low temperature in summer, high preheating temperature and low working temperature can be .

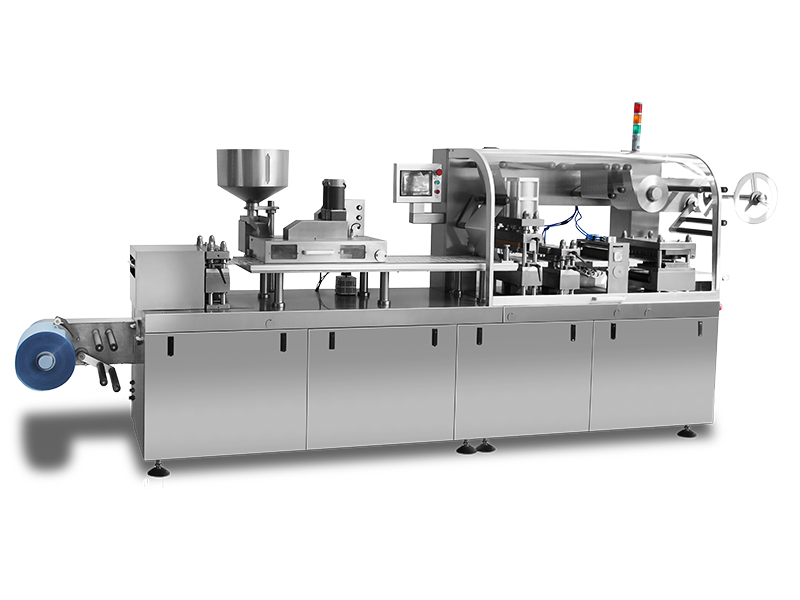

High-quality blister packaging machine is the key to product packaging. Here is an automatic blister packaging machine (DPB-270/360JL aluminum-plastic-aluminum (tropical aluminum) packaging machine)

1. This machine adopts the principle of 270J blister packaging machine, guide rail type, convenient mold adjustment and accurate positioning.

2. Due to the addition of tropical aluminum molding and heat sealing mechanism, the body must be lengthened by 1.8 meters, so it adopts a split structure for easy transportation.

3. This machine adopts servo double traction mechanism, which can avoid the problem of synchronous bubble pressing caused by stoppage, and can easily realize the cursor alignment. The servo air clamp traction facilitates the re-adjustment of the traction length on the man-machine interface when the mold is changed.

High quality blister packaging machine is the key to product packaging.

This is fully automatic blister packaging machine——DPT-260.