How Blister Packing and Cartoning Machines Revolutionize Pharmaceutical Packaging

Release time: 2025-10-13

Table of Contents

In the competitive and regulated pharmaceutical industry, packaging plays a pivotal role in ensuring product safety, integrity, and compliance with industry standards. Among the leading packaging technologies, blister packing and cartoning machines stand out as essential solutions for automating the packaging of pharmaceutical products. These machines are ideal for products like ampoules, oral liquids, lyophilized vials, and pre-filled syringes—offering robust protection, efficiency, and scalability.

This article delves into the applications, benefits, and innovations in blister packing and cartoning machines, and how they streamline pharmaceutical packaging processes.

What Is a Blister Packing Machine?

A blister packing machine is an essential piece of packaging equipment in the pharmaceutical industry, used to package individual pharmaceutical products in sealed compartments made of plastic, often backed by foil or paper. This method ensures that the product remains secure and uncontaminated.

Blister packs are commonly used for tablets, capsules, and other small products. However, these machines are now also adapted for products such as ampoules, lyophilized vials, and pre-filled syringes, providing enhanced protection against external factors like moisture, contamination, and light.

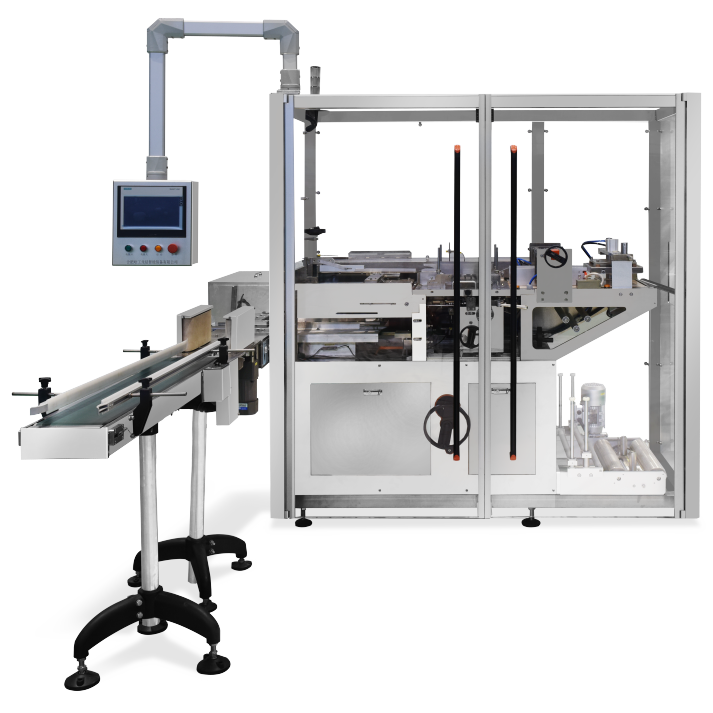

What Is a Cartoning Machine?

Once the blister pack is formed, the cartoning machine takes over to place these sealed blister packs into cartons. These cartons are made from durable materials like paperboard and are often equipped with spaces for product labeling and batch information. Cartoning machines are vital in automating the packing process, reducing manual labor, and ensuring that products are correctly sealed, labeled, and ready for shipment.

Key Applications of Blister Packing and Cartoning Machines

Blister packing and cartoning machines have become indispensable in packaging a wide variety of pharmaceutical products. Some of the most notable applications include:

1. Ampoules and Lyophilized Vials

Ampoules and lyophilized vials contain sensitive pharmaceutical formulations that need robust protection. Blister packing machines seal these products within individual compartments, ensuring they remain safe from contamination or environmental exposure. Cartoning machines then group these units into cartons for added security.

2. Oral Liquids and Pre-Filled Syringes

Packaging oral liquids and pre-filled syringes in blister packs may seem unconventional, but this packaging method provides secure containment and minimizes the risk of leakage or contamination. Blister packing machines are designed to seal these items in individual compartments, while cartoning machines securely box them for distribution.

3. Pre-Filled Syringes

Pre-filled syringes are a popular choice for injectable medications. Blister packing machines are ideal for packaging these syringes, offering protection from external contamination while maintaining easy access. The cartoning machine places the blister-sealed syringes into cartons, ready for use.

4. Other Pharmaceutical Products

Blister packing and cartoning machines are versatile enough to handle a broad range of pharmaceutical products, including tablets, capsules, and diagnostic kits, ensuring that they are safely packaged and ready for distribution.

How Blister Packing and Cartoning Machines Improve Pharmaceutical Packaging

Blister packing and cartoning machines offer a variety of benefits to pharmaceutical manufacturers, including:

1. Increased Efficiency

Automating the blister packing and cartoning process significantly reduces production time. Manufacturers can meet high-volume demand without sacrificing speed or quality. Automation also reduces labor costs, leading to long-term cost savings.

2. Superior Product Protection

One of the primary advantages of blister packaging is its ability to protect sensitive pharmaceutical products. The sealed compartments ensure protection from light, moisture, and contaminants, all of which can affect product quality. This is crucial for preserving the integrity of lyophilized vials and other delicate medications.

3. Accuracy and Precision

With blister packing machines, pharmaceutical products are handled precisely, ensuring accurate dosing, packaging, and labeling. Automated packaging minimizes human errors and reduces the chance of improper handling or contamination.

4. Regulatory Compliance

The pharmaceutical industry is highly regulated, and compliance with Good Manufacturing Practices (GMP) and FDA regulations is essential. Blister packing and cartoning machines are designed to meet these stringent requirements, offering traceability, accuracy, and consistency in every batch.

5. Cost Savings

Although the initial investment in blister packing and cartoning machines may be high, the long-term savings from reduced labor costs, fewer product errors, and less material waste make these machines a cost-effective investment for pharmaceutical manufacturers.

Factors to Consider When Choosing Blister Packing and Cartoning Machines

When selecting blister packing and cartoning machines, manufacturers must evaluate several key factors:

1. Тип продукта

Different pharmaceutical products require different packaging configurations. A machine that works well for tablets may not be suitable for pre-filled syringes. It is essential to choose a machine that can accommodate the specific size, shape, and characteristics of the product being packaged.

2. Production Capacity

The production capacity of blister packing and cartoning machines plays a significant role in meeting market demand. For high-volume manufacturers, selecting machines with a higher output capacity ensures that production remains on schedule.

3. Flexibility and Customization

A flexible machine that can accommodate various product types, blister sizes, and sealing options offers greater versatility. Look for machines that allow for quick changeovers and easy adjustments to accommodate different packaging needs.

4. Ease of Maintenance

Regular maintenance is crucial to keeping packaging machines operating smoothly. Choose machines that are easy to clean, maintain, and repair to minimize downtime and ensure long-lasting performance.

5. Automation and Integration

Many modern blister packing and cartoning machines can be integrated into fully automated packaging lines. This integration minimizes manual handling, reduces errors, and increases efficiency. Look for machines that offer seamless integration with other equipment in your production line.

Conclusion

Blister packing and cartoning machines are vital for automating pharmaceutical packaging, offering unmatched benefits such as increased efficiency, improved product protection, and compliance with regulatory standards. These machines are indispensable in the packaging of various pharmaceutical products, including ampoules, oral liquids, lyophilized vials, and pre-filled syringes.

The advanced technology behind these machines ensures that pharmaceutical manufacturers can meet high demand while ensuring the safety and integrity of their products. Investing in blister packing and cartoning machines is a crucial step toward improving production capabilities, reducing costs, and enhancing product quality in the pharmaceutical industry.