Why Small Business Packaging Automation Is Essential for Growth and Efficiency

Release time: 2025-08-19

Small businesses face numerous challenges when scaling up operations, and one of the most significant hurdles is managing packaging efficiently. As customer demand grows, so does the complexity of packaging orders, leading many small businesses to explore automation. Packaging automation isn’t just a trend; it’s a strategic investment that helps businesses save time, reduce costs, and scale operations efficiently.

In this article, we’ll explore the key benefits of packaging automation for small businesses, provide examples of affordable solutions, and discuss how it can drive growth and improve operational efficiency.

What is Packaging Automation?

Packaging automation refers to the use of machines and technology to automate the packaging process, reducing the need for manual labor. It can include systems for filling, sealing, labeling, and even palletizing products.

For small businesses, automation offers several advantages:

- Increased Speed and Accuracy: Automated systems operate faster than human workers and are less prone to errors.

- Reduced Labor Costs: By minimizing manual labor, businesses can save on employee wages and training costs.

- Scalability: As your business grows, packaging automation systems can scale with you, handling higher volumes without sacrificing speed or quality.

Is Packaging Automation the Right Choice for Your Small Business?

When evaluating whether packaging automation is suitable for your small business, consider these factors:

- Order Volume: If you have a high volume of orders, automation can streamline your processes and improve efficiency.

- Labor Costs: If you’re facing rising labor costs or difficulty hiring skilled workers, automation can help you save significantly.

- Tipo de produto: Automation is particularly beneficial for standard, high-volume products. Custom or fragile items might require more hands-on handling.

If your business aligns with these criteria, then investing in packaging automation could be a game-changer.

Top Cost-Effective Packaging Automation Solutions for Small Businesses

Here are some affordable and scalable packaging automation solutions perfect for small businesses:

- Semi-Automatic Packaging Systems

Semi-automatic systems require minimal human intervention and are a great entry-level solution for small businesses. These machines handle part of the process, such as sealing or labeling, while operators perform the remaining tasks.- Example: A semi-automatic labeling machine can label hundreds of products in an hour, significantly reducing manual labor.

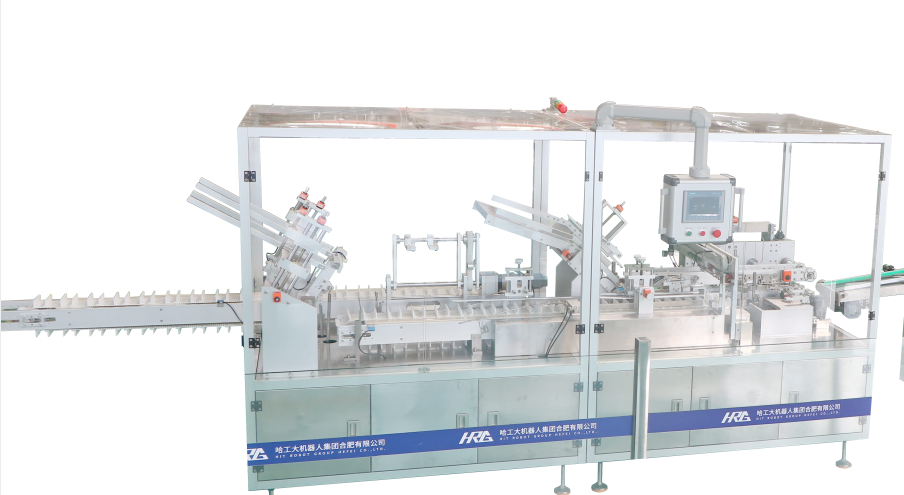

- Fully Automatic Packaging Systems

Fully automated systems can handle entire packaging lines without human intervention. These systems can fill, seal, and label products at a rapid pace, making them ideal for businesses with high-volume needs.- Example: A fully automated filling and capping machine used for liquid products, where the process is entirely automated for speed and consistency.

- Robotic Packaging Systems

Advanced robotic systems can automate tasks like sorting, palletizing, and picking. While they require a larger upfront investment, robotic systems are highly flexible and adaptable to different packaging formats.- Example: A robot that picks and places products into boxes automatically, which increases efficiency and reduces manual handling.

How Packaging Automation Drives Growth for Small Businesses

Packaging automation is not just about saving time; it also drives growth by:

- Improving Product Quality: Automated systems reduce human error, ensuring each package is sealed and labeled consistently.

- Faster Time-to-Market: With automation, businesses can get their products to customers more quickly, improving delivery times and customer satisfaction.

- Enhancing Competitiveness: By lowering costs and increasing efficiency, small businesses can offer better prices and improve their competitive edge in the market.

For example, an e-commerce business can use packaging automation to quickly fulfill large volumes of orders during peak seasons like holidays, meeting customer demand without compromising quality.

Understanding Packaging Automation Costs for Small Businesses

While the upfront cost of packaging automation may seem daunting, the long-term savings and efficiency gains make it a worthwhile investment. Here’s how the cost breaks down:

- Initial Investment: This includes the cost of machines, installation, and training. Semi-automatic systems are more affordable, while fully automated systems can be more expensive but offer higher throughput.

- Ongoing Maintenance: Machines require regular maintenance to ensure they continue running smoothly. However, many packaging automation systems are designed for low-maintenance operation.

- Labor Savings: By reducing the need for manual labor, businesses can recoup their investment over time. For example, businesses may save on hourly wages or the cost of hiring additional staff for peak periods.

A smart way to approach the cost is by performing a ROI (Return on Investment) analysis. This can help determine how long it will take for the system to pay for itself based on labor savings and increased throughput.

How to Get Started with Small Business Packaging Automation

If you’re ready to automate your packaging process, follow these steps to get started:

- Assess Your Needs: Determine your packaging volume, the type of products you’re selling, and your budget.

- Research Automation Solutions: Look into various semi-automatic and fully automatic systems that fit your needs and budget. Be sure to read customer reviews and case studies to understand the effectiveness of each option.

- Invest in Training: Ensure your team is properly trained to operate the new systems efficiently.

- Monitor Performance: Once installed, monitor the performance of your automation systems regularly to ensure they are delivering the expected results.

FAQ: Packaging Automation for Small Businesses

Q1: What are the benefits of small business packaging automation?

A1: Packaging automation increases operational efficiency, reduces labor costs, improves product quality, and scales with business growth while minimizing waste.

Q2: How do I know if packaging automation is right for my business?

A2: If you have a high volume of orders, are facing labor shortages or rising costs, or are struggling to keep up with demand, packaging automation may be the right solution for you.

Q3: What is the cost of packaging automation for small businesses?

A3: Costs vary depending on the system type, but there are affordable options for small businesses. Semi-automatic systems typically offer the best balance of cost and performance.

Final Thoughts

Packaging automation is no longer just for large corporations. Small businesses can benefit from it as well, unlocking new levels of efficiency, scalability, and cost savings. By choosing the right automation solutions, businesses can stay competitive and position themselves for long-term growth.

Ready to streamline your business operations? Contact us today to learn more about affordable packaging automation solutions.