Plate-type Alu/PVC Blister Packing Machine DPP-350

Ver maisProdutos

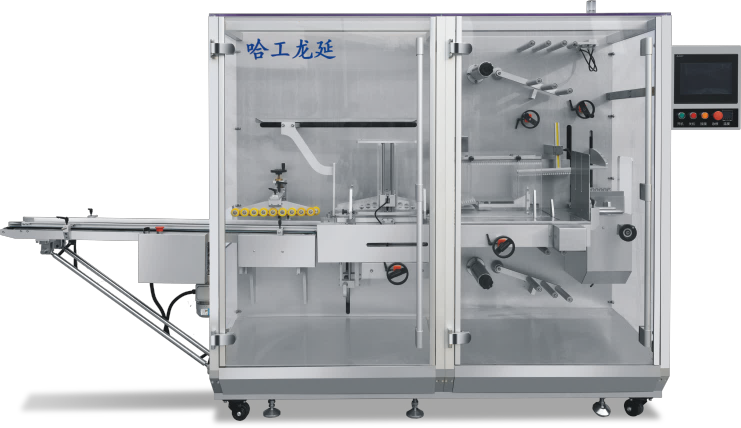

Plate-type Alu/PVC Blister Packing Machine DPP-260G

- Troca rápida

- Precauções onipresentes

- Operação intuitiva

- Integração rigorosa

Tipo de produto

Introdução

Perguntas frequentes

Vídeo

Características:

1. DPP series blister packing machines can be packed in modules to enter 2 meters high elevator and segmented sterilization workshop. It is easy to combine and install by tapered pin positioning and screw fastening.

2. Pull-out drawer-like format makes changing and loading formats easy.

3. Equipped with a photoelectric compensation mechanism, it can perform graphic matching of printed aluminum foil.

4. Frequency converter regulated main motor. The number of punches can be set according to the length of stroke and the difficulty of feeding.

5.Clamping and traction by robot arm and servo drive ensure stable operation and accurate synchronization. Adjustable stroke range of 30-145mm denotes that any size of the blister within this range can be produced.

6.The forming plate and the heating plate open and close automatically. The machine start-up can be delayed when the heating plate is lowered, limiting the wastage within one blister. Contact heating of coupled plates reduces power consumption and temperature, saving energy and increasing the stability of plastic sheet.

7.Air cushion heat sealing is coupled by the upper and lower webs. The air cylinder lifts the web automatically when the machine stops, eliminating blister deformation while extending the machine life.

9. Vibratory feeder is optional to increase feeding efficiency of out-of-shape tablets.

10. Automatic alarm and machine stop, with emergency stop, improve the operator’s safety during machine commissioning and format changing.

11. All parts and hopper that are in contact with pharmaceuticals are made out of 316 stainless steel and non-toxic materials, with GMP compliant.

Parâmetros

| Modelo | DPP-260G | |

| Punching speed (standard 57mm×80mm×4) | PTP/PVC 50 cuts/min Alu/Alu 30 cuts/min | |

| Saída máx. | PTP/PVC 130,000 pockets/hour Alu/Alu 80,000 pockets/hour | |

| Alcance do curso | 40-150 milímetros | |

| Área máxima de formação | 245×130mm | |

| Profundidade máxima de formação | Alu/Alu 12mm PTP/PVC 18mm (customizable 25mm) | |

| Poder de formação e aquecimento | 2 kW (×2) | |

| Poder de selagem a quente | 1.5KW | |

| Fonte de alimentação e potência total | 3-phase 4-wire 380V 50HZ(220V 60HZ)7.5KW | |

| Potência do motor | 3 kW | |

| Fluxo da bomba de ar | ≥0,3m3/min | |

| Packaging materials | PVC | (0.2-0.5)×260mm |

| PTP | (0.02-0.05)×260mm | |

| Alumínio | (0.09-0.15)×260mm | |

| Dimensões (C×L×A) | 4600×1200×1700mm | |

| Dimensões da embalagem (C×L×A) | 5000×1300×1800mm | |

| Peso | 3000 kg | |

Produtos relacionados