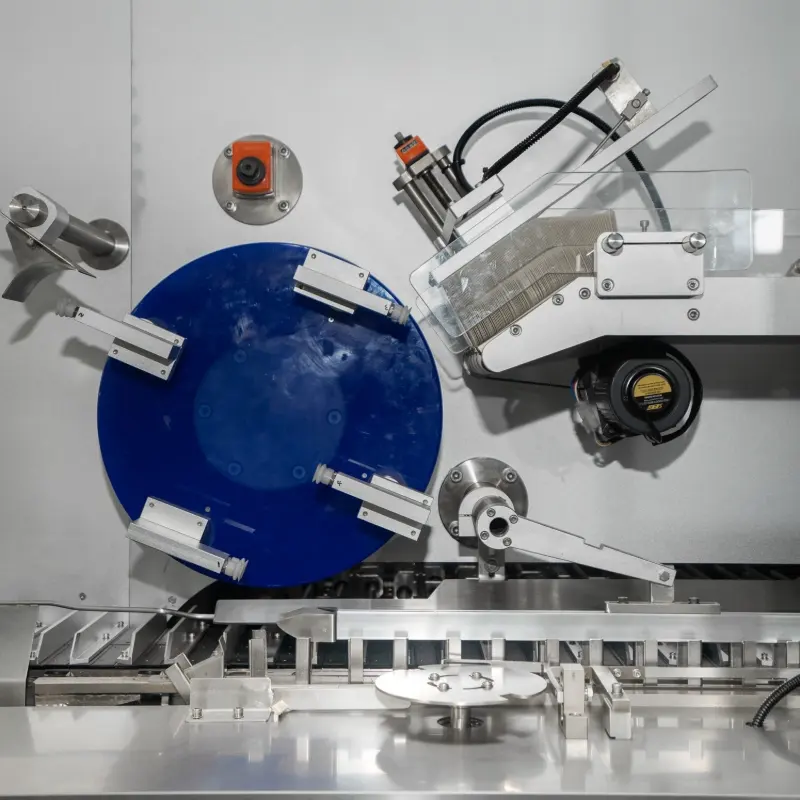

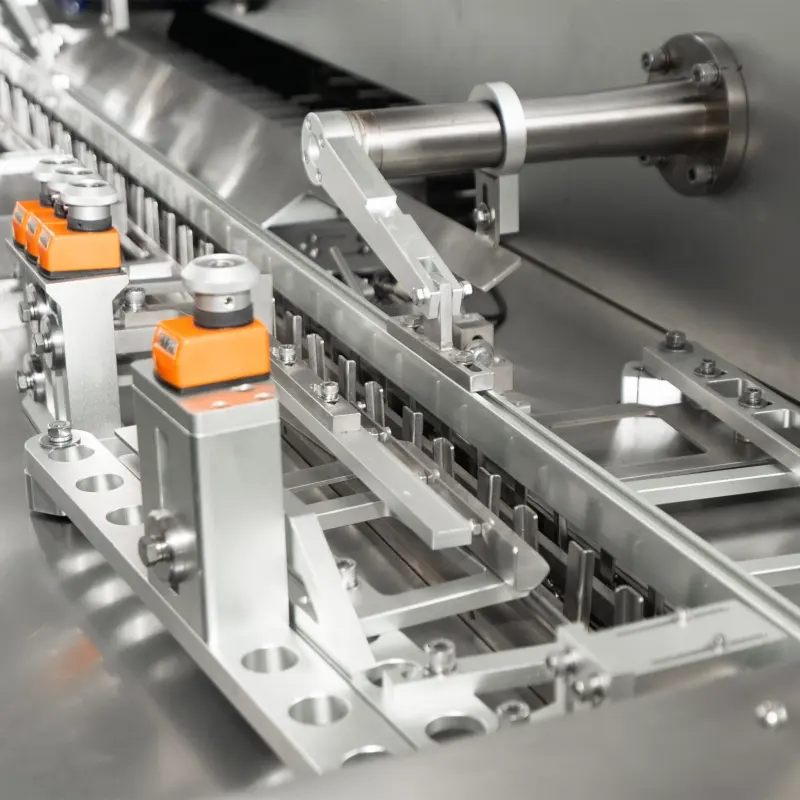

High-speed automatic continuous Cartoner ZHJ300 is a new model independently developed by our parent company, a high-tech product integrating technologies of photo electronics, pneumatics and mechanics. The design prototype is based on packing multiple sizes of bottles and leaflets, with maximal cartoning speed of 300 cartons per minute. It is also applicable to automatic loading and cartoning of bar-shape products, ointments and sachets. Inline material conveying and inspection, carton pick-up forming and conveying, material feeding, batch mark embossing, top and bottom tuck in locking (or hot melt gluing), empty carton rejection and final product discharging are all processed automatically. The machine can be integrated with blister machine, sachet packing machine, liquid filling machine, cellophane overwrapping machine (stretch bander), case packer and other machines for mass production.

Tray Making,Loading, Lamination and Cartoning Machine DPT350W+ZHJ300

View More