Why Automatic Cartoning Machines Are Essential for Your Business

Release time: 2025-06-30

In the competitive manufacturing world, efficiency, precision, and cost-saving solutions are essential. One of the best ways to achieve these goals is by investing in automatic cartoning machines. These innovative machines have revolutionized packaging in industries such as food, pharmaceuticals, and consumer goods. They help businesses streamline processes, boost productivity, and reduce costs.

This article highlights the many benefits of automatic cartoning machines and why they are a must-have for businesses aiming to improve their packaging operations.

Table of Contents

What is an Automatic Cartoning Machine?

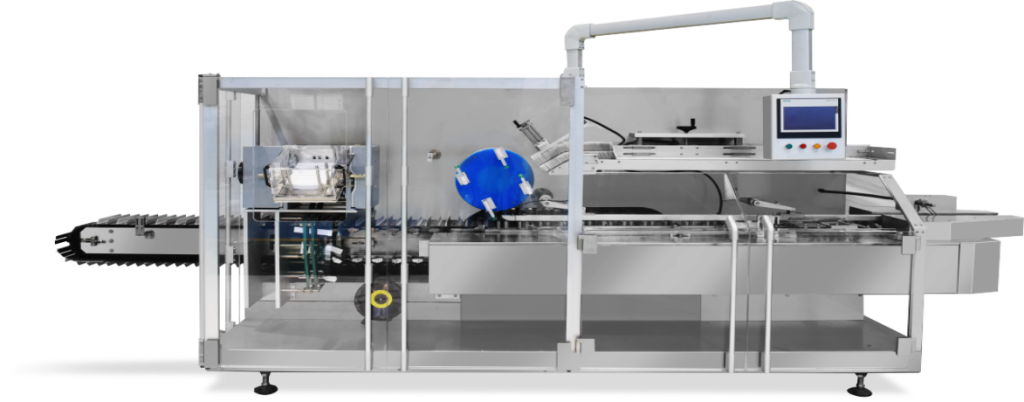

An automatic cartoning machine is a piece of equipment that automatically forms cartons, loads products, and seals them for shipping. This process is crucial for industries that require speed, consistency, and large-scale production.

The machine operates in several stages: forming a carton from flat cardboard, inserting products, and sealing the carton. Once sealed, the carton is ready for labeling and distribution. With automatic cartoning machines, packaging becomes an automated, reliable, and efficient task.

Key Features of Automatic Cartoning Machines

To better understand why automatic cartoning machines are essential for your business, here are the key features and components:

- Carton Forming – The machine automatically forms a flat piece of cardboard into a functional carton. This step eliminates manual labor and ensures precise carton alignment.

- Product Insertion – After carton formation, products are automatically inserted into the cartons. These can include food items, bottles, jars, or consumer goods.

- Sealing Mechanism – The sealing mechanism ensures the carton is securely sealed, protecting the product during transportation. Sealing can be done using glue, tape, or other methods.

- Labeling System – Some automatic cartoning machines also apply labels with product information, barcodes, or branding, ensuring compliance with regulations and providing essential product details.

- Control System – Modern machines feature programmable touchscreens for operators to easily manage settings, including packaging size, speed, and product type.

Why Invest in an Automatic Cartoning Machine?

When deciding whether to invest in an automatic cartoning machine, consider the long-term benefits:

1. Boost Efficiency and Speed

Automatic cartoning machines drastically increase packaging speed, handling large volumes faster than manual processes. This reduces downtime and enhances production output.

2. Save on Labor Costs

Automating packaging reduces the need for manual labor, which translates to significant cost savings. Fewer employees are required for packaging, and the likelihood of human error is minimized.

3. Consistent Quality and Precision

Automatic machines ensure that each carton is formed, loaded, and sealed with uniformity, providing high-quality, reliable packaging that meets industry standards.

4. Enhanced Workplace Safety

By minimizing the need for manual labor, especially in repetitive and physically demanding tasks, automatic cartoning machines help reduce workplace injuries.

5. Minimized Material Waste

Automation optimizes the use of packaging materials, reducing waste. Precise material control helps you save money while contributing to more sustainable operations.

6. Customizable for Different Product Types

One of the greatest advantages of automatic cartoning machines is their flexibility. These machines can easily accommodate different product types and sizes, whether it’s food, pharmaceuticals, or consumer goods.

How Automatic Cartoning Machines Are Shaping the Future of Packaging

As technology advances, so does the future of packaging. Automatic cartoners are at the forefront of this evolution.

Smart Integration and Maintenance

Today’s automatic cartoning machines often include smart technology, such as sensors and predictive maintenance capabilities. These technologies help identify faults before they occur, preventing downtime and reducing costly repairs.

Sustainable Packaging Solutions

With growing environmental concerns, automatic cartoning machines contribute to sustainability by reducing material waste and increasing packaging efficiency. These machines can also be set up to handle eco-friendly materials, supporting your commitment to sustainability.

Greater Flexibility for Custom Orders

With customer demand for more variety and quicker production times, automatic cartoning machines provide the flexibility to quickly change packaging configurations with minimal downtime.

Industries That Benefit from Automatic Cartoning Machines

Here are some industries that benefit from automatic cartoning machines:

- Food and Beverage: Packaged snacks, meals, and drinks benefit from faster, more efficient packaging.

- Pharmaceuticals: Ensure proper sealing and labeling for regulatory compliance.

- Cosmetics: Efficient packaging for beauty and skincare products.

- Consumer Goods: Automate packaging for items such as toys, electronics, and retail products.

Conclusion

In today’s competitive market, efficiency, cost-effectiveness, and quality are crucial to success. Automatic cartoning machines offer numerous benefits, including increased production speed, reduced labor costs, and consistent packaging quality. These machines help businesses streamline their operations and ensure the safety and efficiency of their packaging processes.

By upgrading to an durable automatic cartoning machine, your business can reduce waste, boost efficiency, and improve its overall packaging quality, which is vital for long-term growth.