Blister Packing Machine DPT-420L

Voir plusProduits

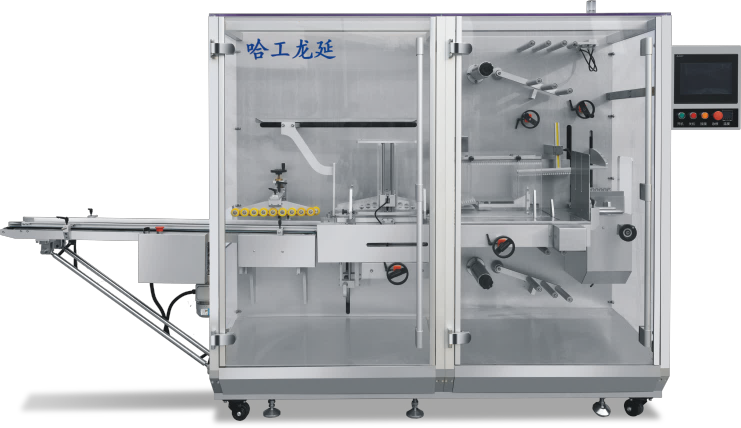

Tray Making, Loading, Lamination and Cartoning Machine DPT350W + ZHJ200

- Changement rapide

- Précautions omniprésentes

- Fonctionnement intuitif

- Intégration étroite

Type de produit

Introduction

FAQ

Vidéo

Tray module

1. Main synchro mechanism and main motor installed back side makes maintenance easy. Timing belt transmission reduces noise and oil pollution.

2. Workstation can be adjusted by handwheel with digital display.

3. Segmental pre-heating results in better forming effects. Heating plates can be separated and displaced after shutdown to avoid damage to packing materials.

4. Traction mechanism controlled by servo motor renders stable performance and accurate synchronization.

5. Film splicing and joining station facilitates faster changeover of packing materials.

6. Robotic feeding ensures accurate placement of product without damaging blisters.

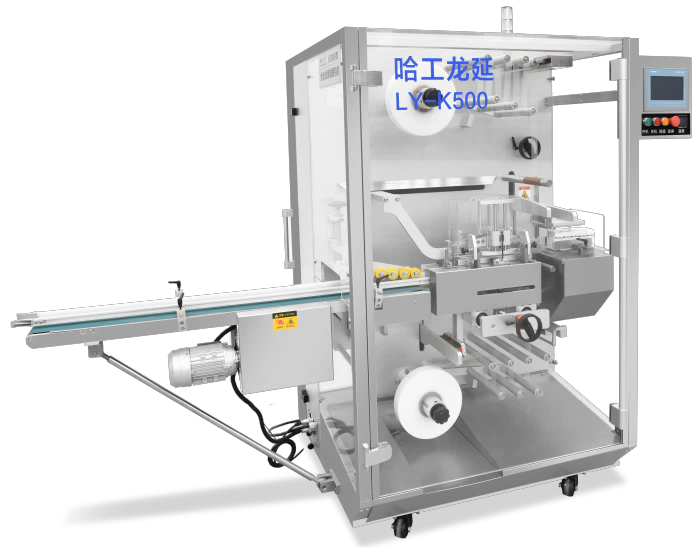

Carton module

7. Continuous Cartoner ZHJ200 is a high-tech photoelectric, pneumatic and mechanical machine, applicable to a wide range of , blisters, drug bottles, ointments and other similar products.

8. It has fully automatic process of products conveyance and detection, leaflet folding (1-4 times) and transmission, leaflet detection, carton pick-up, erecting and transmission, products into cartons, batch mark embossing, carton sealing (tuck-in or hot melt adhesive). It’s also the right choice for integrated production and mass production.

9. User-friendly PLC+HMI with photoelectric detection.

10. The touch screen has the code and address of each sensor actuator, helping trace the consequences caused by malfunctions.

11.Overload monitoring system minimizes damage. The machine will stop automatically and the overloading part will be displayed on the touch screen.

Paramètres

| Modèle | DPT350W+ZHJ200 | |

| Tray module | Punching speed | 10–30 cuts/min (depending on blister size) |

| Packaging materials | PVC/PVDC Max. width: 350mm thickness:0.15~0.50mm | |

| Scope of application | vials, ampoule, oral liquid, others on request | |

| Main functions | heating-forming-detecting-tracting-laminating-punching-feeding-transmitting | |

| Profondeur de formage max. | 25mm (customizable≤45mm) | |

| Surface de formage max. | 345x150mm | |

| Plage de course | standard≤150mm (customizble≤250mm) | |

| Alimentation électrique | 380 V 50 Hz | |

| Puissance totale | 9kw | |

| Air comprimé | 0.5~0.7MPa | |

| Cooling water consumption | tap water circular cooling/chiller | |

| Bruit | 40-70dB | |

| Dimensions (L × l × H) | 4800X1170X2100 | |

| Poids | 3000kg | |

| Cartoner module | Carton size(L×W×H) | Max:210×108×65mmMin:70×20×16mm |

| Leaflet size(LxW) | (100-180)x(100-280)mm | |

| Leaflet quality | 60-65g/m2 | |

| Sortir | 60-200 cartons/min | |

| Puissance du moteur principal | 2,2 kW | |

| Motor frequency | 0-50Hz | |

| Certificates | ISO9001:2000; CE | |

| Warranty | 1 year | |

Produits connexes