Imprimantes à jet d'encre multi-têtes HP LYJET-4

Voir plusMachines d'emballage sous blister

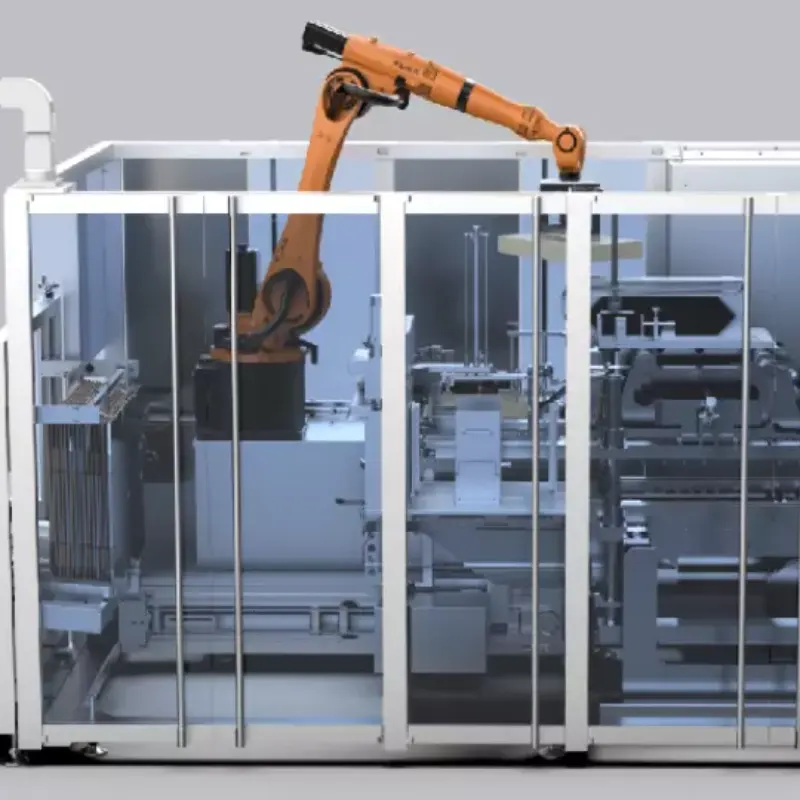

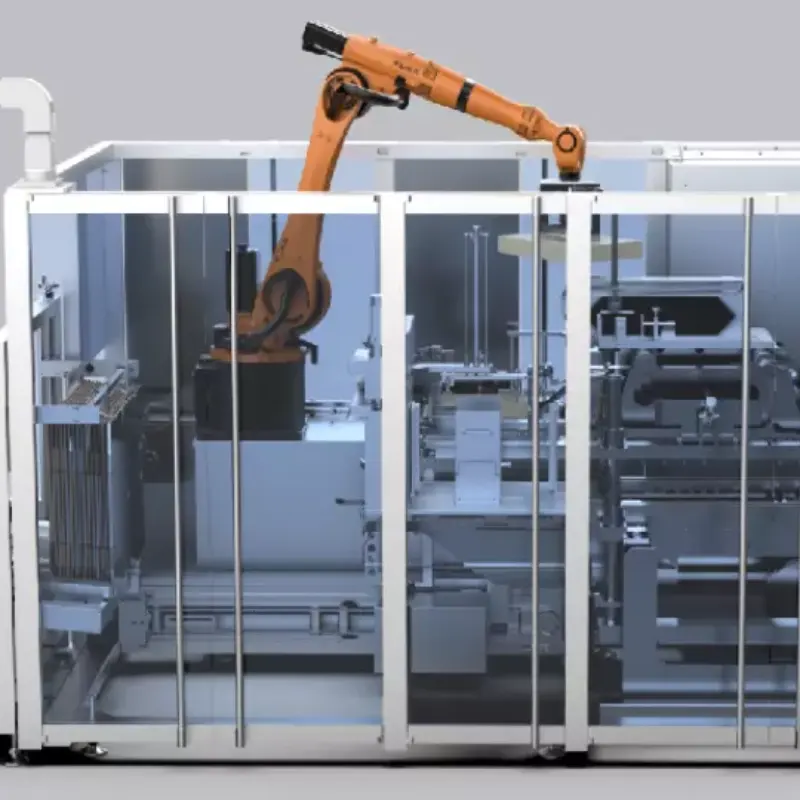

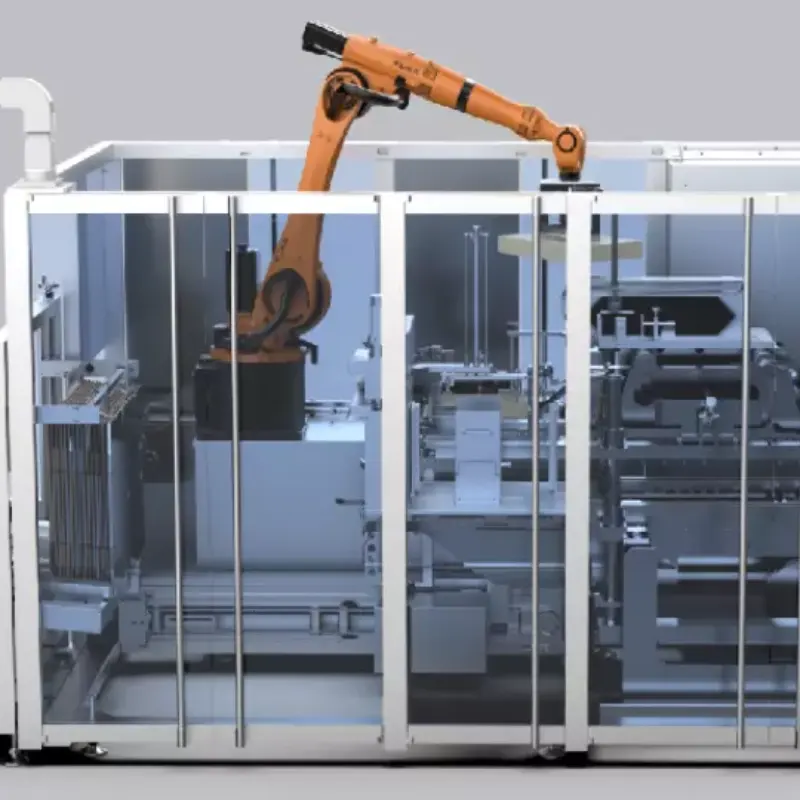

Machine d'emballage sous blister en aluminium et PVC à rouleaux

- Changement rapide

- Précautions omniprésentes

- Fonctionnement intuitif

- Intégration étroite

Type de produit

Introduction

FAQ

Vidéo

Product Features

1. Equipped with a 360° rotary high-speed vacuum suction plate rejecting and conveying device, a shared decelerator for both rejection transmission and stroke transmission ensures synchronization of rejection speed and stroke speed.

2. Water cooling device for the roller die sustains the continuous use of the heat-sealing roller die in the production process, avoids the impact on the blister by the high temperature of the roller, and effectively eliminates aluminum foil wrinkling caused by the heat radiation.

3. The main drive connection by synchro-pulley and synchro-belt avoids vibration caused by the transmission under high-speed operation and reduces the noise of the equipment.

4. The process of forming, heat sealing, batch coding, punching and cutting each controlled by separate decelerators, driven by shafts and connecting pendulum rods, allows faster speed, higher level of durability and lower noise.

| Modèle | DPH-260 | DPH-360 |

| Punching speed (Alu/PVC) | 40-180 cuts/minute | 40-180 cuts/minute |

| Production capacity | 14400-43200 blisters/hour | 14400-54000 blisters/hour |

| Plage de course | 40-240mm | |

| Surface de formage max. | 260x240mm | 360x240mm |

| Power 3-phase 5-wire 380V 50Hz (220V 60Hz) | 21Kw | 24.4Kw |

| Dimensions (LxWxH) | 4700x1200x1800mm | 4800x1600x1800mm |

| Poids | 3000 kg | 3500Kg |

aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa

-

Q

What maintenance services does HGDLY offer?

HGDLY offers a comprehensive range of maintenance services, including equipment inspections, preventive maintenance, repairs, and spare parts supply. Visit their website or contact their customer service team for detailed information on their maintenance offerings. -

Q

Produits connexes