How to Select an Automatic Facial Mask Cartoner for 2025

Release time: 2025-12-09

Table of Contents

As the demand for skincare products, particularly facial masks, continues to grow globally, the packaging process must evolve to meet the challenges of a rapidly changing market. In 2025, manufacturers need faster, more efficient, and automated solutions to maintain product quality and meet consumer expectations. One such solution is the Automatic Facial Mask Cartoner. This article will guide you through the process of selecting the perfect automatic cartoner for your facial mask production line, ensuring you stay ahead in the competitive packaging landscape.

What is an Automatic Facial Mask Cartoner?

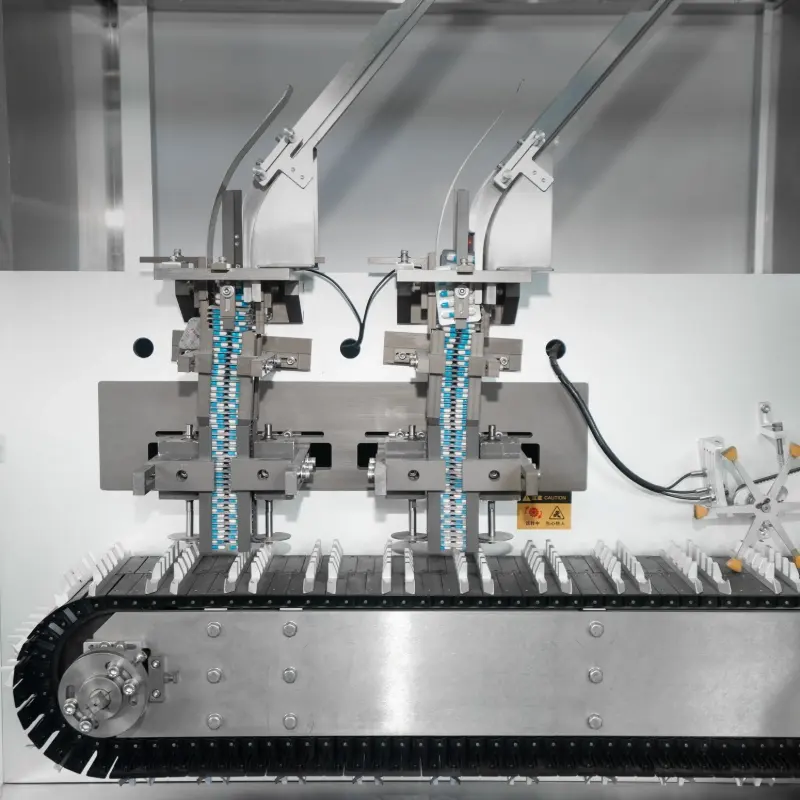

An Automatic Facial Mask Cartoner is a type of packaging machinery designed to efficiently pack individual facial mask packets into cartons. These machines offer high-speed automation, accuracy, and precision in the cartoning process, making them an essential part of modern mask production lines.

In 2025, automation in packaging is not just a trend but a necessity for companies looking to keep up with growing consumer demand while ensuring hygiene, consistency, and branding excellence. These machines handle large volumes of masks per minute, thus reducing human error, enhancing productivity, and keeping labor costs low.

Key Features of an Automatic Facial Mask Cartoner:

- High-Speed Packaging: Can process hundreds of masks per minute.

- Precision Handling: Ensures accurate placement of products without damaging the delicate masks.

- Flexible Design: Accommodates a variety of mask shapes and sizes.

- Automation: Reduces the need for human intervention, streamlining the production process.

Why Automation is Key in 2025

The year 2025 will see even more demand for skincare products, and facial masks are no exception. The need for packaging solutions that can:

- Handle higher volumes.

- Integrate seamlessly into existing production lines.

- Maintain a high level of quality control.

An automatic facial mask cartoner helps meet these demands by automating the cartoning process, ensuring faster and more reliable packaging while lowering operational costs. This shift toward automation isn’t just a matter of convenience but is critical for keeping up with market trends and consumer expectations in the skincare industry.

Key Factors to Consider When Choosing an Automatic Facial Mask Cartoner for 2025

When selecting an automatic facial mask cartoner, there are several factors to consider to ensure it aligns with your production goals for 2025. The following guide covers the essential points to help you make an informed decision:

1. Speed and Throughput Requirements

Speed is one of the most critical factors when selecting a cartoner. The packaging machine’s speed should align with your production volume. For 2025, the demand for facial masks is expected to continue its upward trajectory. Therefore, you need a cartoner that can handle large quantities of masks per minute while maintaining product quality.

- Consideration: Determine your daily or weekly packaging requirements and ensure the cartoner’s speed matches or exceeds these needs.

- Recommendation: Choose a machine capable of packaging at least 200-300 masks per minute, depending on your production scale.

2. Flexibility for Mask Variations

Facial masks come in various types, sizes, and shapes, from single-sheet masks to multi-pack and premium masks. It’s crucial to select a cartoning machine that is adaptable to different packaging formats, especially if your production line includes diverse mask products.

- Consideration: Opt for a machine that allows easy adjustments for different types and sizes of facial masks.

- Recommendation: Look for a modular design that supports quick and easy format changes.

3. Integration with Existing Packaging Line

In 2025, manufacturers are increasingly seeking packaging solutions that can easily integrate with other machines in their production lines. An automatic cartoner should seamlessly integrate with your existing filling, sealing, and labeling systems. Integration reduces the chances of error and ensures smooth operation from start to finish.

- Consideration: Ensure the machine can work with your current packaging setup, including labelers and fillers.

- Recommendation: Choose a cartoner that offers flexible integration with different types of machinery, whether it’s horizontal, vertical, or semi-automatic systems.

4. Ease of Operation and Maintenance

In the fast-paced production environment of 2025, ease of operation is essential. The machine should be user-friendly, with simple controls and minimal training required for operators. Additionally, a robust maintenance plan is necessary to ensure that your cartoner functions efficiently with minimal downtime.

- Consideration: Choose a machine with an intuitive control system and an easy-to-understand user interface.

- Recommendation: Ensure the cartoner is made from high-quality, durable materials (like stainless steel) and includes features that make maintenance straightforward.

5. Machine Customization and Scalability

Your production needs will likely evolve over time. When selecting a cartoning machine, choose one that offers customizable settings and is easily scalable. This ensures your investment will grow with your business.

- Consideration: Assess if the machine can be easily upgraded with new features or attachments to accommodate future growth.

- Recommendation: Look for machines with adjustable settings for carton sizes and speeds, as well as scalability for increased production.

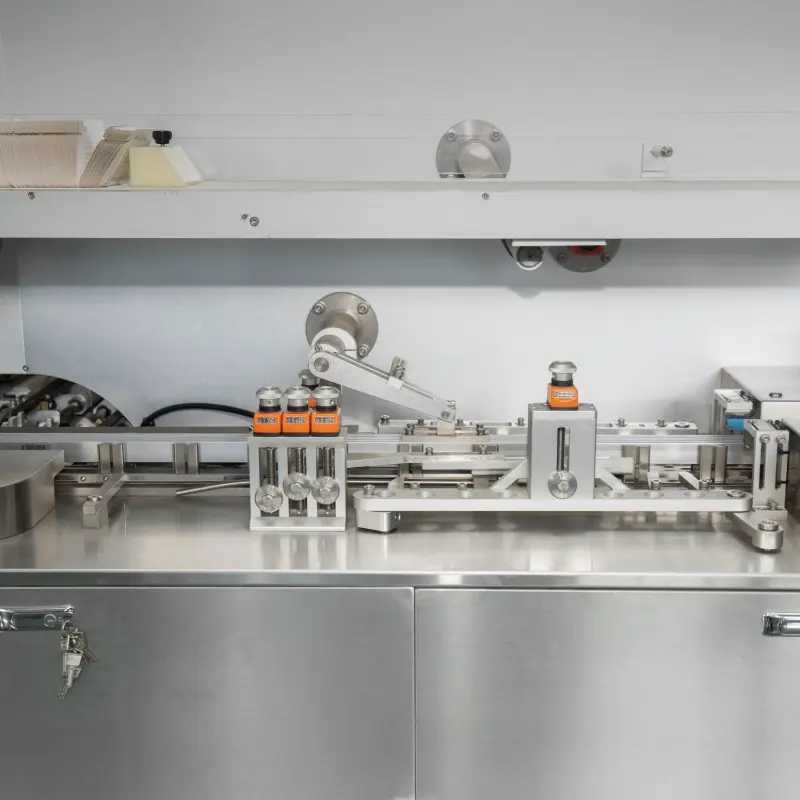

6. Product Safety and Hygiene

Facial masks are delicate products, often designed for sensitive skin. Ensuring that they are handled in a hygienic environment is paramount. A high-quality automatic cartoner should offer features that protect the integrity of the product during packaging.

- Consideration: Ensure that the cartoner is designed to minimize product contact, reducing the risk of contamination.

- Recommendation: Look for machines that meet international hygiene standards and have features such as anti-static capabilities and minimal product contact.

7. Cost vs. Value

While cost is always a factor in purchasing decisions, in 2025, it’s important to consider the long-term value a cartoner provides. While high-end models may have a higher upfront cost, their efficiency and longevity can lead to significant savings in labor and maintenance costs over time.

- Consideration: Evaluate the overall cost-effectiveness of the machine, including its energy consumption and longevity.

- Recommendation: Choose a machine that balances initial cost, operating cost, and productivity gains over time.

Why Choose HGDLY for Your Facial Mask Cartoning Needs?

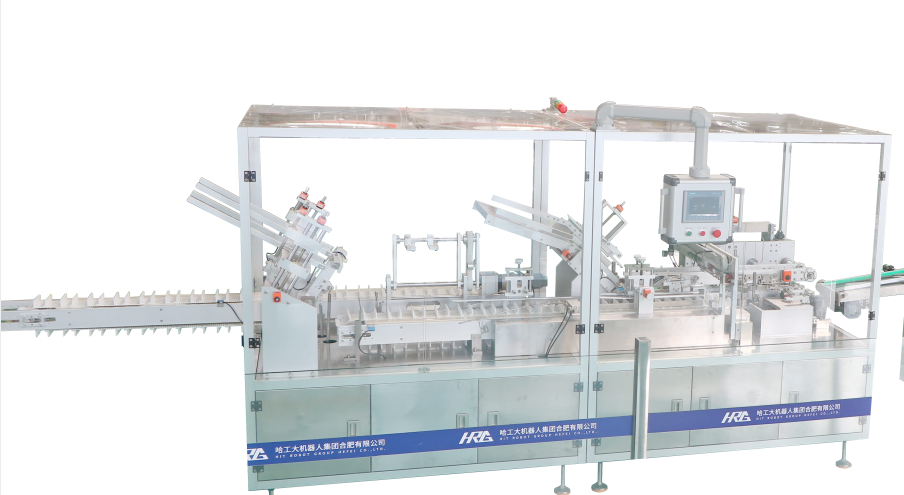

As a professional facial mask cartoner manufacturer, HGDLY has built a strong reputation for producing reliable, high-performance packaging solutions tailored to the needs of the cosmetic and skincare industry. Their machines are engineered with precision to meet the diverse needs of facial mask packaging, ensuring high-speed, hygienic, and efficient operations.

Key Features of HGDLY Cartoners:

- Customizable Solutions: HGDLY offers flexible packaging machines that can be tailored to your specific needs.

- Advanced Technology: Their cartoners are equipped with cutting-edge automation technology, ensuring consistent and high-quality packaging.

- Durability and Reliability: HGDLY machines are designed to last, reducing downtime and improving production efficiency.

- Compliance with Hygiene Standards: HGDLY machines meet global hygiene standards, ensuring safe and sanitary packaging of facial masks.

Choosing HGDLY as your partner means investing in quality and innovation. Their machines are designed to support your growth and adapt to future needs, ensuring you stay competitive in the evolving skincare market.

Conclusion

Selecting the right automatic facial mask cartoner for your business in 2025 is more critical than ever. By focusing on speed, flexibility, integration, ease of use, scalability, hygiene, and cost, you can make an informed decision that enhances your production efficiency, ensures quality packaging, and reduces costs. As consumer demand for facial masks continues to rise, a well-chosen cartoning machine will not only optimize your production line but also position your brand as a reliable and professional player in the competitive skincare market.

HGDLY, a trusted facial mask cartoner manufacturer, offers machines that meet the evolving needs of the facial mask industry, providing high-quality packaging solutions that support your business growth. Stay ahead of the competition by investing in a cartoning solution that fits your needs today while preparing you for growth in the future.