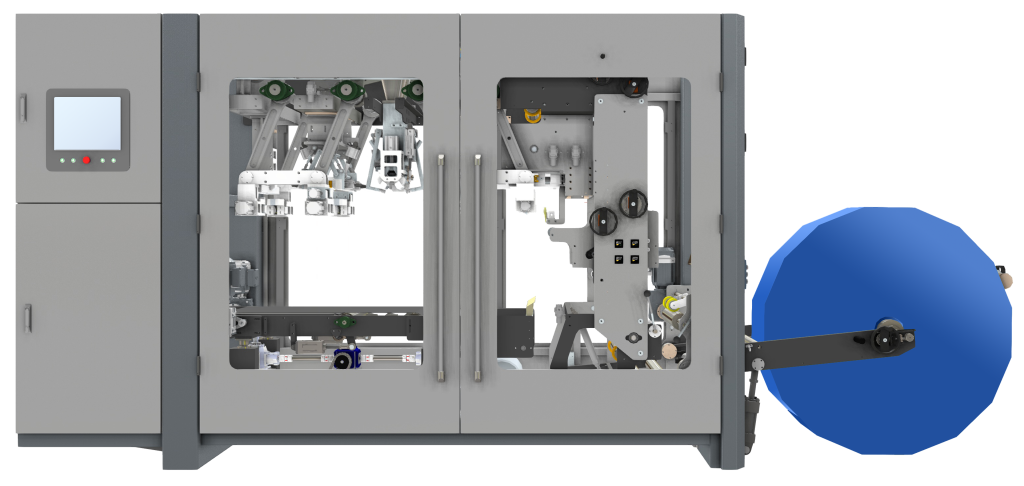

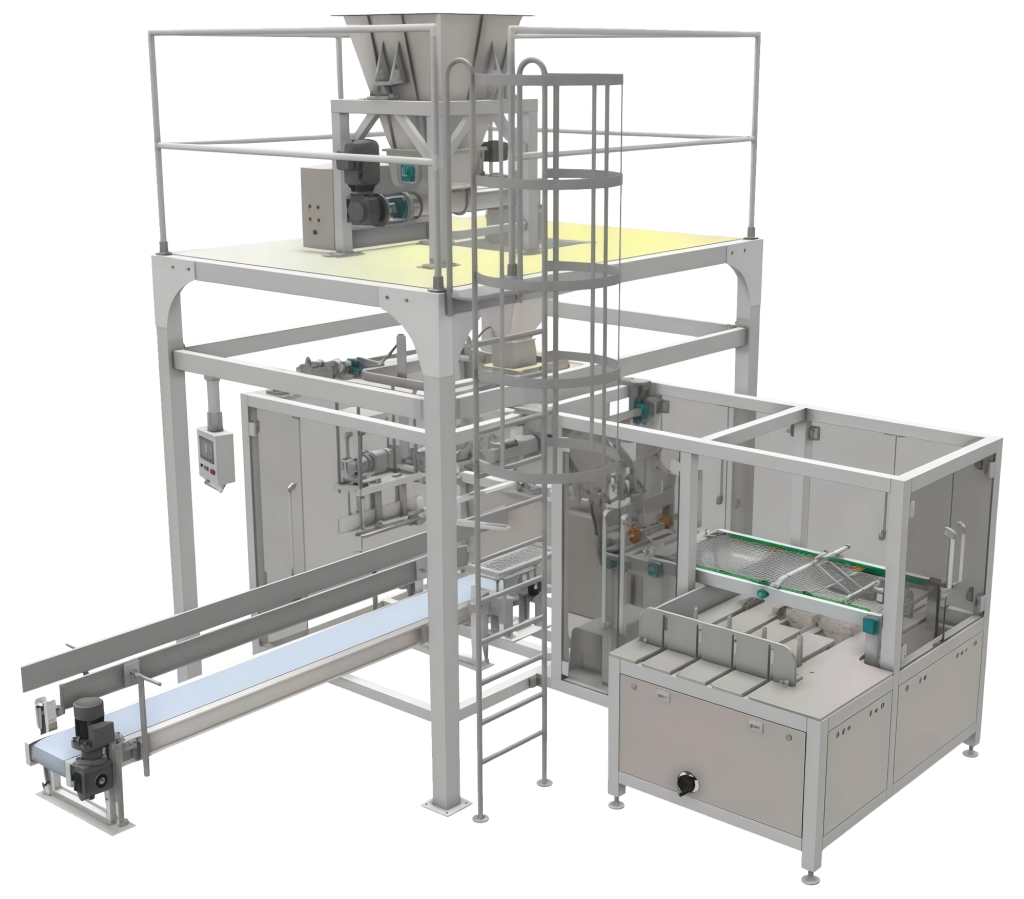

FFS is the abbreviation of Form-Fill-Seal packaging machine. The system can continuously

complete bag making, metering filling, sealing, and other functions at one time. FFS

Advantages

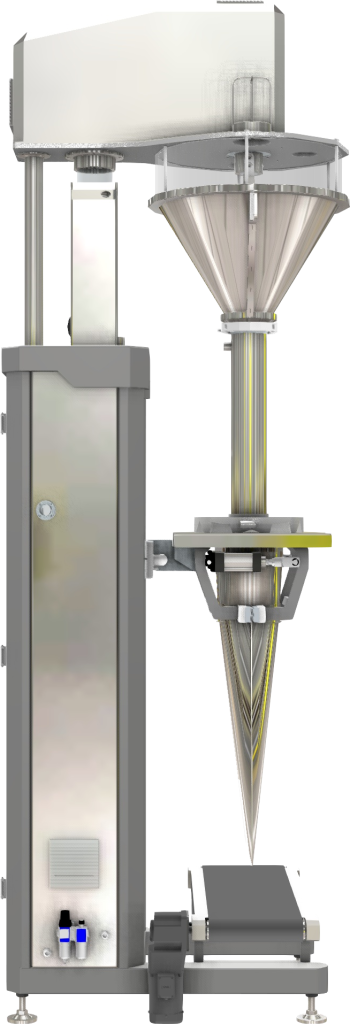

Compared with the original open-bag packaging, the FFS film rolls used by Longyan Intelligent have the advantages of good heat-sealing effect, stable performance, and low packaging material cost. During the packaging process, FFS can discharge excess air through maze-like perforations to ensure that special materials, such as materials with poor fluidity, can remain stable during packaging and transportation. In addition, the entire packaging process of FFS is clean and efficient, and the equipment and packaging materials meet the EU environmental protection requirements, truly realizing environmentally friendly production packaging.

| Sortir | 600-800 bags/hour | 1200-1500 bags/hour |

| Product | Granules, powder | |

| Scope of application | PE film roll; M bag | |

| Bag size | L(650-900)mm W(360-420)mmM fold(50-80)mm*2 | |

| Sealing | pulse-type heat-sealing | |

| Accuracy | ±20-50g | |

| Bag weight | 20-50KG/bag | |

| Materials | Regular products: Carbon steel with spray-coating, and the material-contact surface is made of 304 stainless steel.Corrosive products: Entirely made of 304 stainless steel. | |

| Optional function | Feeding methods: gravity feeding, belt feeding, vibrating feeding, combined feeding | |

| Weighing type | Net weight type or gross weight type | |