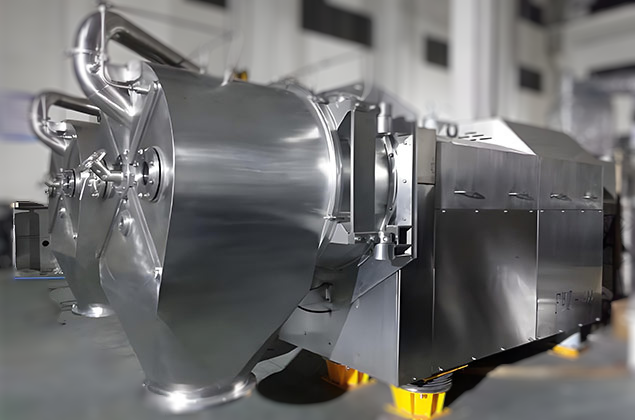

FGD wet flue gas desulfurization technology is usually used in the desulfurization process of sulfur dioxide which produced in some production processes, such as non-ferrous smelting, thermal power plants, waste incineration plants, cement plants. The gypsum produced by the FGD process can be separated from the mother liquor by GLZ desulfurization gypsum centrifuge and cleaned. The finished product can be used to make gypsum board for construction and special gypsum board (sound insulation board). Etc.) or as an additive and filler material.

Centrifugeuse à filtre inversé modèle FWZ

Voir plus