How Carton Packaging Machines Work?

Release time: 2025-08-05

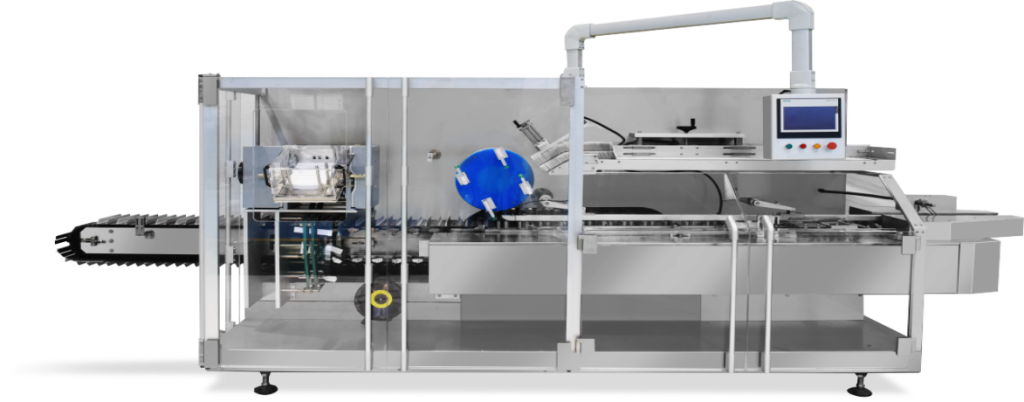

Carton packaging machines are a cornerstone of the modern packaging industry. These machines automate the process of carton erecting, product insertion, sealing, and securing, all of which help streamline production, reduce manual labor, and improve packaging efficiency. In this step-by-step guide, we’ll walk you through how carton packaging machines work, highlighting key stages in the automated packaging process.

1. Carton Loading: The First Step in Automated Packaging

The first step in the carton packaging process involves loading empty cartons into the machine. Cartons are typically stored flat and fed into the packaging system automatically. Advanced carton packaging machines use an automatic loading system that ensures each carton is positioned correctly to begin the erecting process.

Key Point: Carton loading is crucial to ensuring that the subsequent stages are performed efficiently without delays.

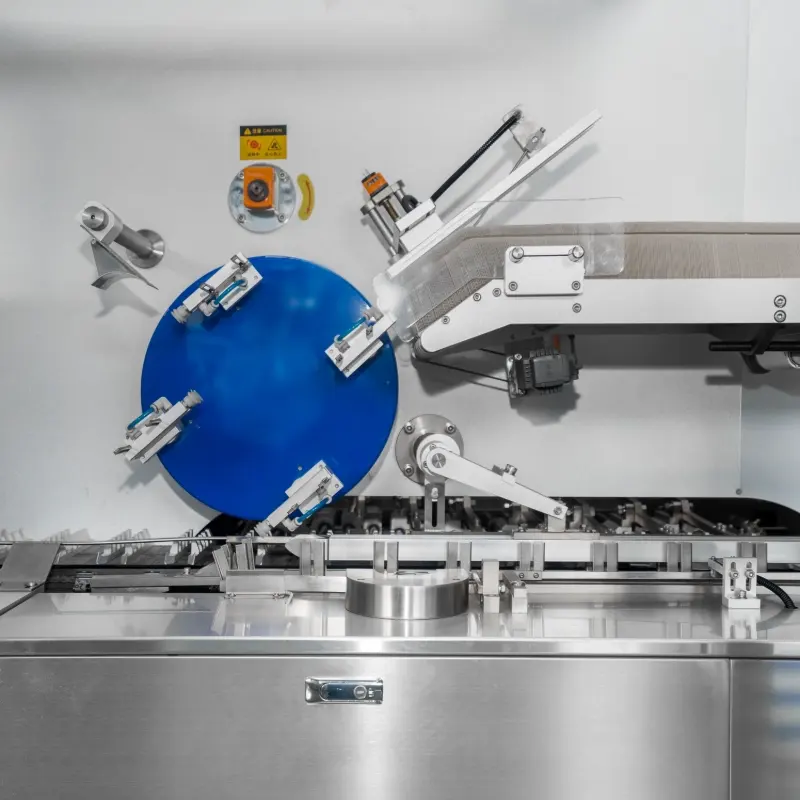

2. Carton Erecting: Folding and Shaping the Carton

Once the cartons are loaded into the machine, the next step is carton erecting. The machine automatically folds and shapes the flat carton into its desired box form. This stage often includes adding glue or tape to ensure that the carton stays in its box shape.

Key Point: Carton erecting machines can handle different types of cartons, including those with various sizes and shapes, depending on the product to be packaged.

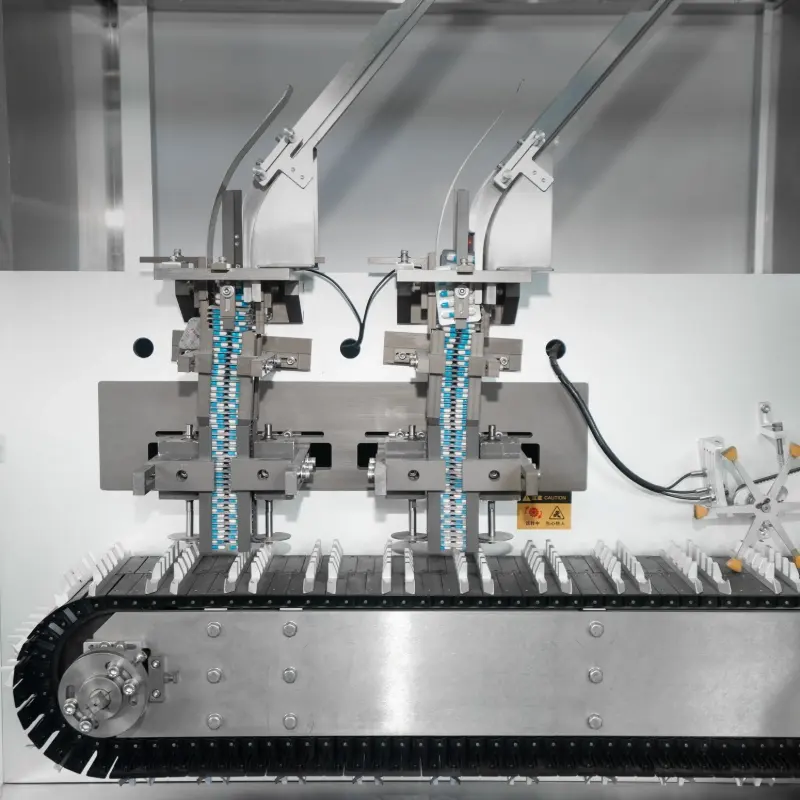

3. Product Insertion: Efficient Packaging Process

After the carton has been erected, the next step is product insertion. This phase involves placing the product into the carton. Automated machines can handle a variety of products, from food items to electronics, ensuring fast and accurate placement. Some systems are even capable of inserting multiple products simultaneously.

Key Point: The speed and precision of product insertion is a vital feature that ensures packaging efficiency in high-volume production lines.

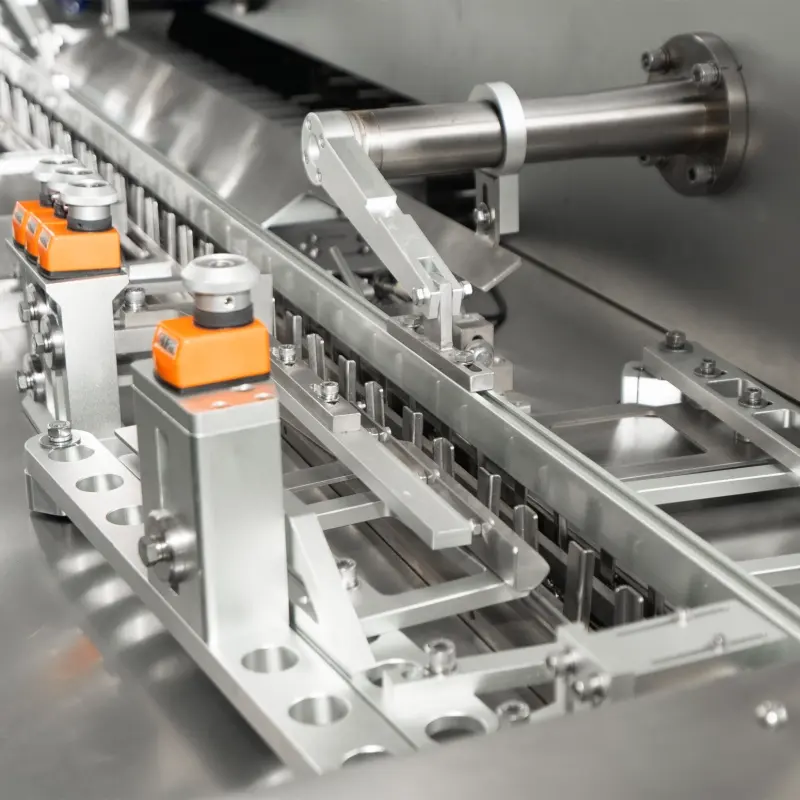

4. Carton Closing: Ensuring a Tight Seal

Once the product is inserted, the carton needs to be sealed. This is done by folding the top flaps of the carton and securing them using glue, tape, or mechanical fasteners. The closure process is essential to ensure that the product stays safe during transport and storage.

Key Point: A tight seal is critical in protecting products from damage and contamination during distribution.

5. Sealing and Securing: The Final Step in Carton Packaging

The final stage of the packaging process is sealing and securing the carton. Automated sealing machines apply pressure to the top flaps, ensuring that the carton is tightly closed. The machine then securely seals the carton, which is ready for shipment. Some machines may also print batch information or other details on the sealed carton for identification.

Key Point: The sealing process not only ensures that the product stays secure, but also improves the overall aesthetics of the packaging, with professional finishes.

6. Output and Discharge: Packaging for Distribution

Once the carton is fully sealed, the finished product is ejected from the machine and ready for storage or shipment. The packaging system automatically sorts the packed cartons, either stacking them for storage or sending them to a conveyor system for further handling.

Key Point: Efficient output and discharge ensure that the packed cartons are quickly ready for distribution, increasing throughput.

How Carton Packaging Machines Optimize Packaging Processes

The primary benefit of using carton packaging machines is the automation of the packaging process. Here’s how they help:

- Time Savings: Automated machines are faster than manual packaging, leading to reduced production time.

- Consistency: Machines provide uniform packaging, which is essential for high-quality products.

- Cost Efficiency: Automation reduces the need for manual labor, lowering overall operational costs.

- Scalability: Machines can handle larger volumes of products, making them suitable for high-demand production environments.

Key Benefits of Carton Packaging Automation

Investing in carton packaging machines offers multiple benefits to businesses:

- Increased Efficiency: Streamlined operations and fewer errors result in better productivity.

- Improved Safety: Automation reduces the risk of injuries from manual labor.

- Customizability: Machines can be adapted to fit different sizes, shapes, and types of cartons to meet specific business needs.

- Reduced Waste: With precise cutting, folding, and sealing, less material is wasted, reducing overall costs.

Conclusion

Carton packaging machines play a pivotal role in modern manufacturing, offering automation and efficiency at every step of the packaging process. From carton erecting to product insertion and sealing, these machines reduce the reliance on manual labor and improve production rates. Understanding how carton packaging machines work is essential for businesses looking to optimize their packaging lines and keep up with industry demands.

Interested in upgrading your packaging process? Contact HGDLY to learn how our automated carton packaging machines can improve your efficiency!

FAQ:

1. What types of products can be packaged using carton packaging machines?

Carton packaging machines can be used for a wide range of products, including food, electronics, pharmaceuticals, and consumer goods.

2. How do carton packaging machines help reduce packaging costs?

By automating the packaging process, carton packaging machines reduce the need for manual labor, increase packaging speed, and reduce material waste, leading to significant cost savings.

3. Are carton packaging machines customizable?

Yes, many carton packaging machines can be customized to handle different sizes, shapes, and packaging materials to suit the specific needs of a business.