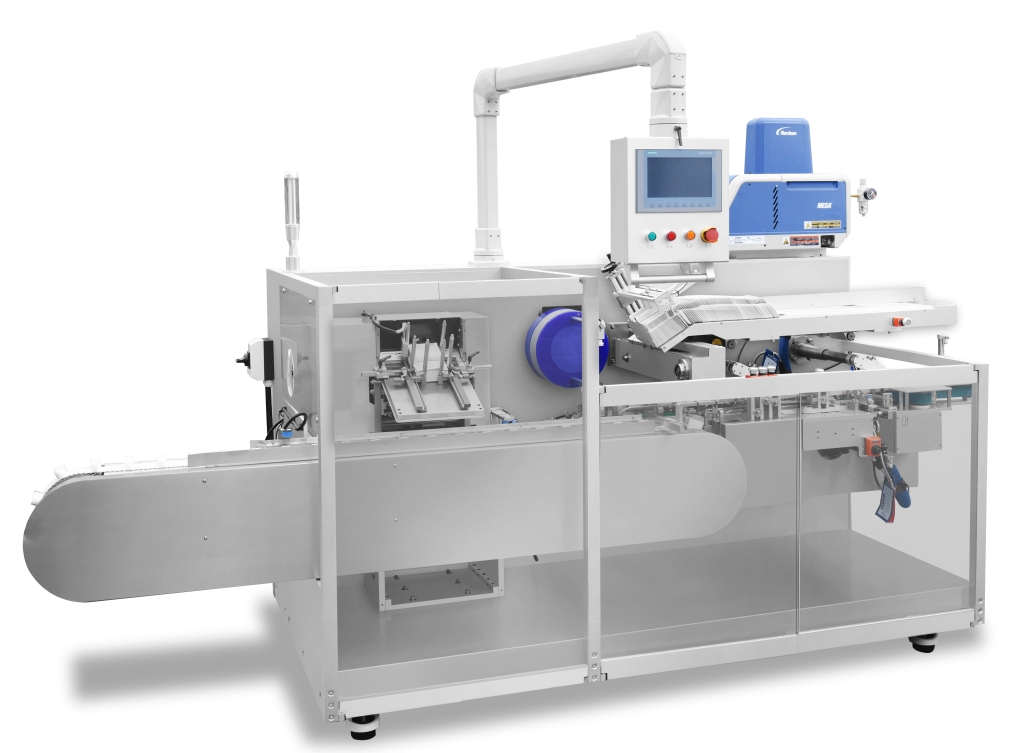

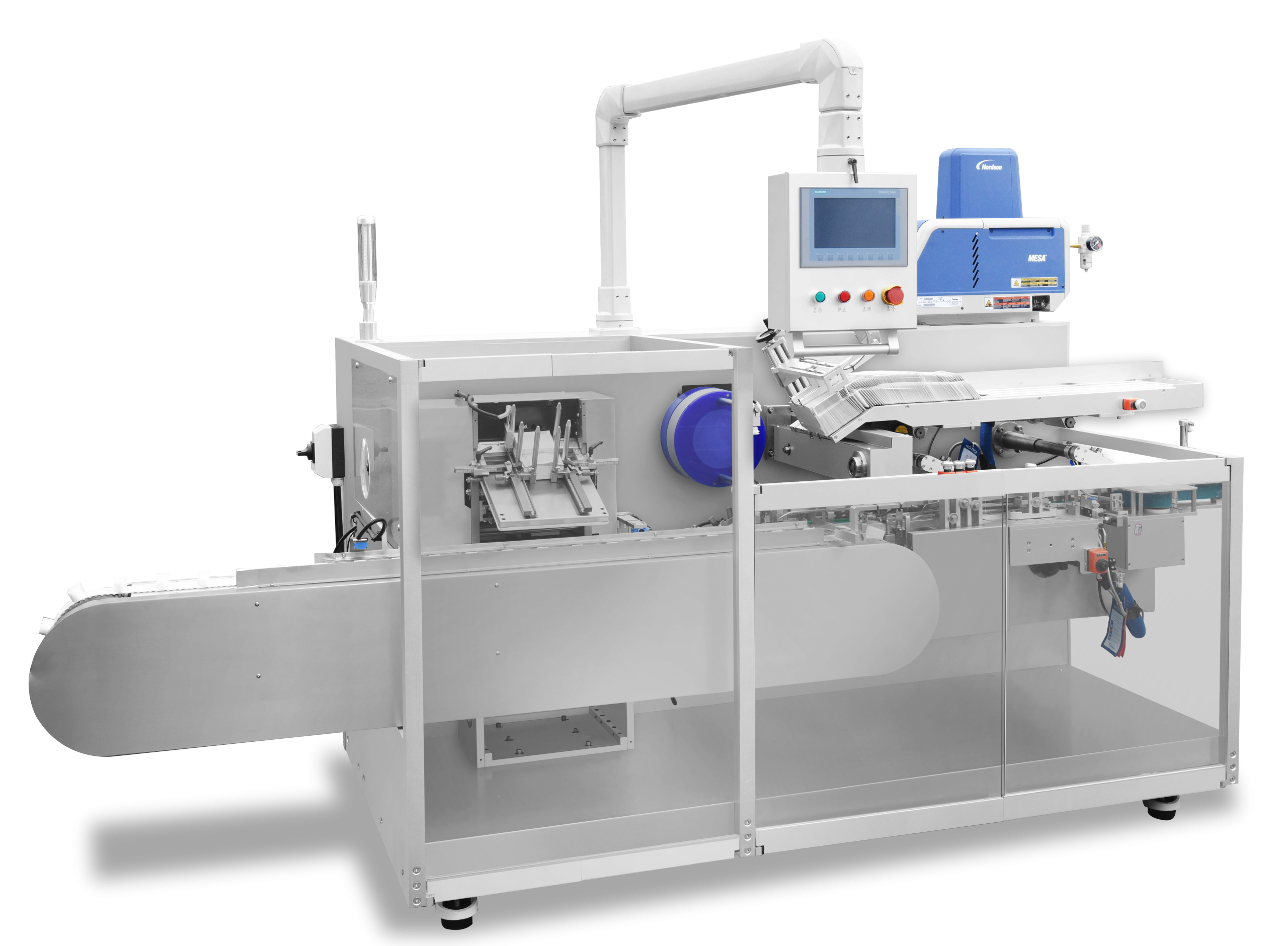

Intermittent Cartoner ZH120 is a high-tech photoelectric, pneumatic and mechanical machine, applicable to medicine trays, blisters, drug bottles, cosmetics and other similar products. Easy to changeover and adjust different sizes of cartons. Fully automatic process of leaflet folding, carton forming, loading of product and leaflet, batch mark embossing, carton sealing and carton discharging. A chain of protective devices ensures safe and efficient operation. The machine can be integrated with Blister Packing Machine, Blister Machine, Sachet Packing Machine, Weight Checker, Cellophane Overwrapping Machine (Stretch Bander), Cartoner to form a one-stop production line.

Tray Making, Loading, Lamination and Cartoning Machine DPT350W + ZHJ120

View More