The Benefits of Automatic Intermittent Cartoners in Modern Manufacturing

Release time: 2026-01-12

Table of Contents

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. One innovative solution that has transformed packaging processes is the automatic intermittent cartoner. This article explores what automatic intermittent cartoners are, their key features, benefits, applications, integration capabilities, and future trends in the industry.

What are Automatic Intermittent Cartoners?

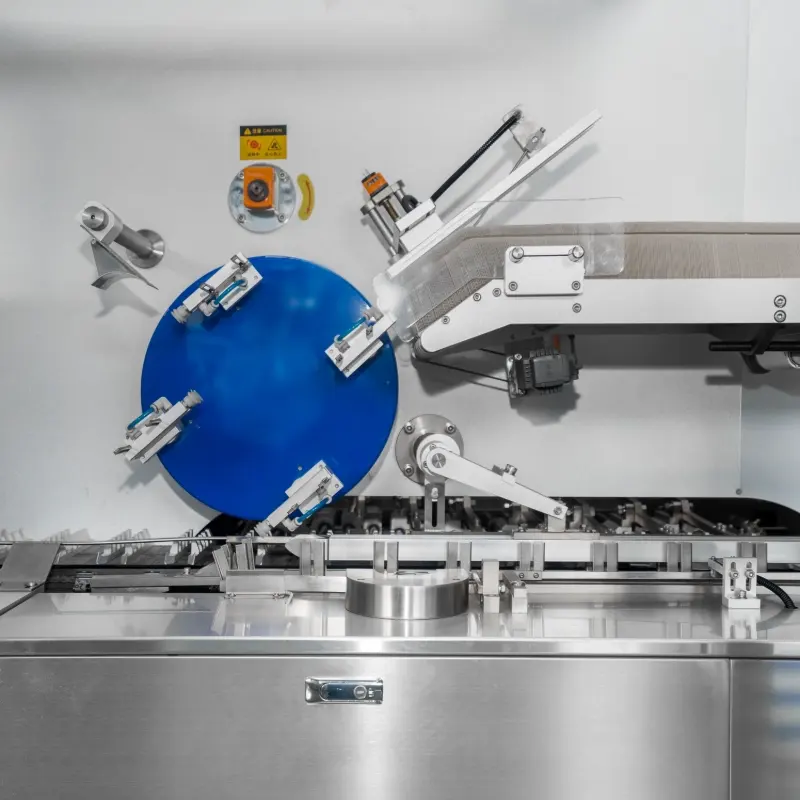

Automatic intermittent cartoners are specialized machines designed to automate the process of forming, filling, and sealing cartons. Unlike continuous motion cartoners, these machines operate in cycles, allowing for precise placement and handling of products. By streamlining the packaging process, they significantly reduce labor costs and increase throughput.

Key Features of Automatic Intermittent Cartoners

Automatic intermittent cartoners come with a variety of advanced features that enhance their functionality:

- High-Speed Operation: Capable of processing hundreds of cartons per minute.

- Flexibility in Packaging: Can handle different carton sizes and shapes, making them suitable for various industries.

- User-Friendly Design: Intuitive controls and easy maintenance reduce downtime.

- Safety Mechanisms: Equipped with safety features to protect operators and minimize accidents.

These features make automatic intermittent cartoners an essential asset for modern packaging lines.

Benefits of Using Automatic Intermittent Cartoners

The adoption of automatic intermittent cartoners brings numerous advantages to manufacturers:

- Increased Efficiency: Automating the cartoning process reduces cycle times and boosts production rates.

- Cost Savings: Lower labor costs and minimized material waste contribute to overall savings.

- Improved Product Quality: Consistent carton formation and sealing enhance product integrity and reduce defects.

- Enhanced Safety: Automation reduces the risk of injury associated with manual handling.

By leveraging these benefits, companies can enhance their operational performance and maintain a competitive edge.

Applications of Automatic Intermittent Cartoners

Automatic intermittent cartoners are versatile machines used across various industries, including:

- Pharmaceuticals: For packaging medication in secure, tamper-evident cartons.

- Food and Beverage: Ideal for packaging snacks, drinks, and other consumables.

- Cosmetics: Used for filling and sealing cartons for beauty products.

- Electronics: Commonly used for packaging small electronic devices or components.

Their adaptability makes them suitable for diverse packaging needs, ensuring that products are delivered safely and efficiently.

Integration Capabilities of Automatic Intermittent Cartoners

One of the standout features of automatic intermittent علب الكرتون is their ability to integrate seamlessly with existing production lines. They can be connected with:

- Blister Packing Machines: For pharmaceutical products requiring additional protection.

- Weight Checkers: To ensure consistent product weight within cartons.

- Labeling Systems: For accurate labeling and tracking of packaged goods.

This integration capability enhances workflow efficiency, reducing bottlenecks and improving overall productivity.

Future Trends in Automatic Intermittent Cartoners

As technology continues to evolve, several trends are shaping the future of automatic intermittent cartoners:

- Smart Technology Integration: IoT-enabled machines for real-time monitoring and predictive maintenance.

- Sustainability in Packaging: Increased focus on eco-friendly materials and processes.

- AI and Robotics: Enhanced automation through artificial intelligence and robotic systems for improved accuracy and efficiency.

These trends indicate a shift towards more intelligent and sustainable manufacturing practices.

Conclusion

Automatic intermittent cartoners are revolutionizing the packaging landscape in modern manufacturing. With their advanced features and numerous benefits, they are a vital investment for companies looking to enhance efficiency, reduce costs, and improve product quality. As the industry continues to evolve, staying informed about the latest trends and technologies will be crucial for maintaining a competitive edge.

For more information on how automatic intermittent cartoners can benefit your manufacturing process, contact هجدلي or explore our range of packaging solutions.

التعليمات

What industries benefit from using automatic intermittent cartoners?

Industries such as pharmaceuticals, food and beverage, cosmetics, and electronics benefit significantly from using automatic intermittent cartoners for their packaging needs.

How do automatic intermittent cartoners improve manufacturing efficiency?

They enhance efficiency by automating the cartoning process, reducing production time, minimizing errors, and allowing for faster changeovers between different products.

Are automatic intermittent cartoners customizable?

Yes, many automatic intermittent cartoners can be customized to handle various carton sizes and types, making them versatile for different packaging requirements.