Complete Guide to Carton Packaging Machines: Types, Benefits & How They Work

Release time: 2025-07-21

A carton packaging machine is a crucial part of modern manufacturing, automating the process of packaging products into durable cartons. This technology streamlines production, reduces manual labor, and increases efficiency. In this guide, we’ll explore how carton packaging machines work, their types, benefits, and how they can optimize your packaging process.

What is a Carton Packaging Machine?

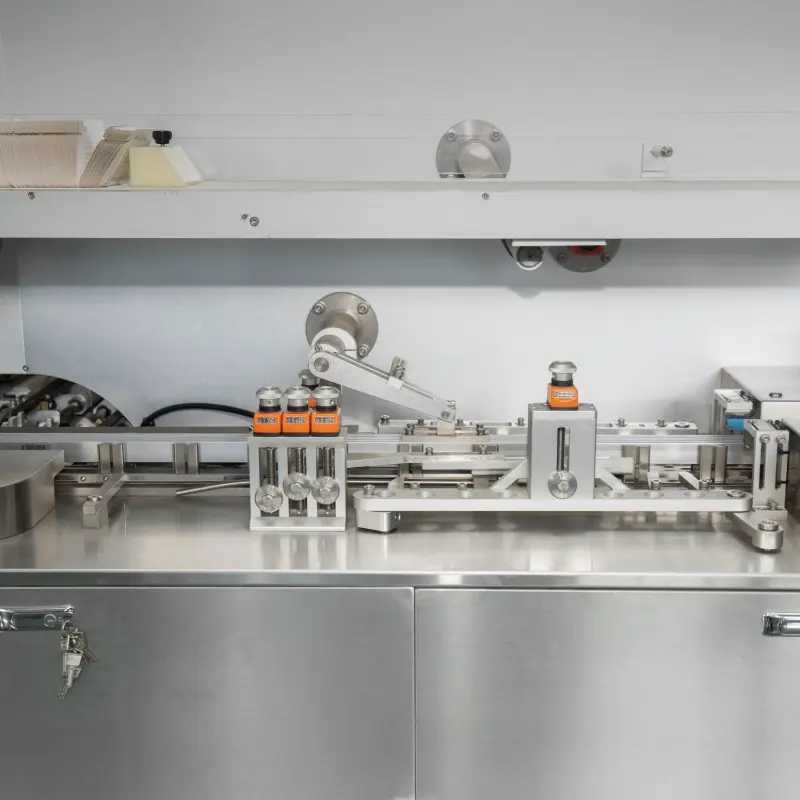

A carton packaging machine is an automated system used to package products into sturdy cartons. These machines form the cartons, fill them with products, and seal them—often without the need for human intervention. This automation significantly improves speed, consistency, and precision in packaging operations, especially in industries like food, pharmaceuticals, and consumer goods.

How Does a Carton Packaging Machine Work?

A carton packaging machine works by automatically performing several tasks:

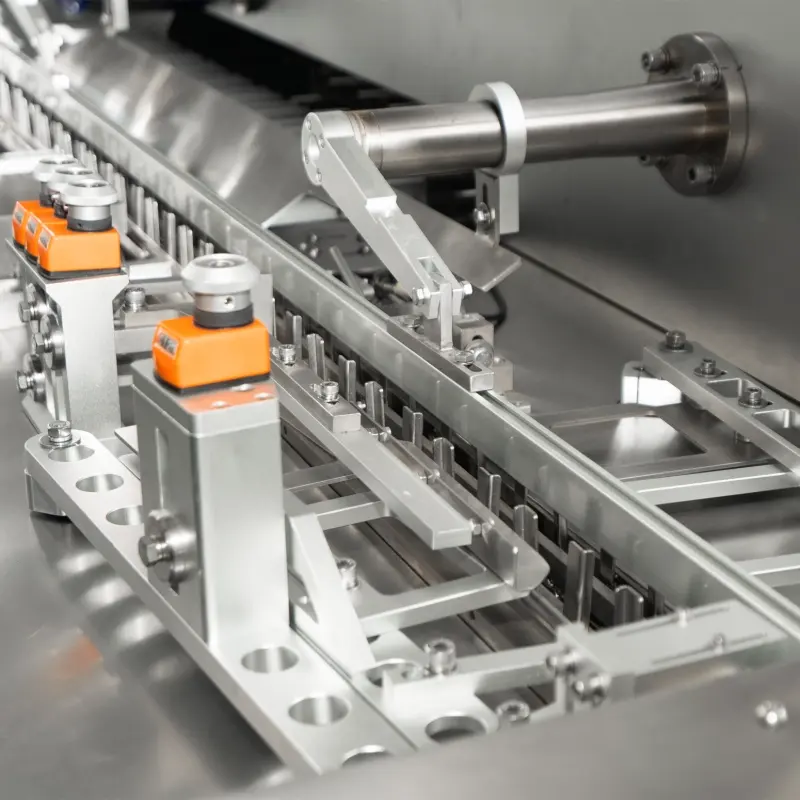

- Carton Formation: The machine takes flat carton blanks and folds them into box shapes.

- Product Filling: It then fills these cartons with products, either through conveyor belts or manual loading.

- Sealing: The machine seals the cartons using glue, tape, or staples.

By automating these steps, the machine reduces the need for manual labor and increases packaging speed, making it essential for high-volume production lines.

Key Benefits of Carton Packaging Machines

1. Cost Savings

By reducing the reliance on manual labor, Cartoning machines help businesses lower operational costs. Machines increase efficiency and can run 24/7, meaning fewer workers are needed, reducing labor costs and minimizing errors.

2. Increased Production Speed

These machines are much faster than manual packaging methods. For example, they can fill and seal hundreds or thousands of cartons in an hour, which helps meet high production demands and tight deadlines.

3. Enhanced Consistency

Automating the packaging process ensures each carton is consistently packed, improving product quality and customer satisfaction. The machines provide a uniform standard of packaging, reducing human error.

4. Improved Product Protection

The automated sealing process ensures that each carton is tightly sealed, providing better protection for the products during transportation. This is especially important for fragile or perishable goods.

Types of Carton Packaging Machines

There are several different types of carton packaging machines designed for various packaging needs. These include:

- Automatic Carton Erectors: These machines form the cartons automatically from flat blanks, preparing them for product filling.

- Carton Filling Machines: These machines fill the cartons with products like bottles, cans, or boxes. They can handle a variety of products, including liquid, solid, and irregularly shaped items.

- Carton Sealers: These machines seal the filled cartons, ensuring they are tightly closed for storage and shipment. They use tape, glue, or staples for sealing.

Other variations include semi-automatic machines and manual systems, depending on production volume and complexity.

How Much Does a Carton Packaging Machine Cost?

The cost of a carton packaging machine varies widely depending on the machine’s capacity, features, and level of automation. Prices can range from a few thousand dollars for small-scale machines to tens of thousands for high-capacity, fully automatic systems.

Factors like customization, speed, and brand also affect the price. It’s important to assess your production needs and budget before making a purchase.

FAQ about Carton Packaging Machines

1. What is a carton packaging machine?

A carton packaging machine automates the process of packaging products into cartons. It improves speed, reduces human error, and lowers labor costs.

2. How does a carton packaging machine work?

A carton packaging machine folds, fills, and seals cartons automatically. It ensures faster and more consistent packaging than manual methods.

3. What are the benefits of carton packaging machines?

Key benefits include cost savings, increased production speed, consistency, and improved protection of products.

4. What types of carton packaging machines are there?

Common types include automatic carton erectors, filling machines, and sealers, each designed for specific tasks in the packaging process.

5. How much do carton packaging machines cost?

The price varies based on capacity and features, ranging from thousands to tens of thousands of dollars.

Conclusion

Carton packaging machines are vital for improving efficiency, consistency, and cost-effectiveness in production lines. Whether you’re packaging food, electronics, or pharmaceuticals, choosing the right machine can streamline your operations and boost your business’s bottom line.

If you’re considering a آلة تغليف الكرتون for your operations, it’s important to evaluate your production needs and explore different types of machines to find the best solution for your business.

Looking for the right carton packaging machine for your business? Contact هجدلي for personalized recommendations and pricing!