All-in-One Case Packers: The Ultimate Automated Solution for Efficient Packaging

Release time: 2025-11-27

In today’s fast-paced industrial landscape, efficient packaging systems are essential for maximizing productivity and ensuring the safe handling of products. All-in-one case packers have emerged as the ultimate solution for businesses looking to automate and streamline their packaging process. By consolidating multiple tasks into a single machine, these automated systems are transforming the packaging industry across sectors, offering speed, flexibility, and cost savings.

In this article, we’ll explore what all-in-one case packers are, how they work, the advantages they provide, and why they are becoming indispensable for companies in various industries.

What are All-in-One Case Packers?

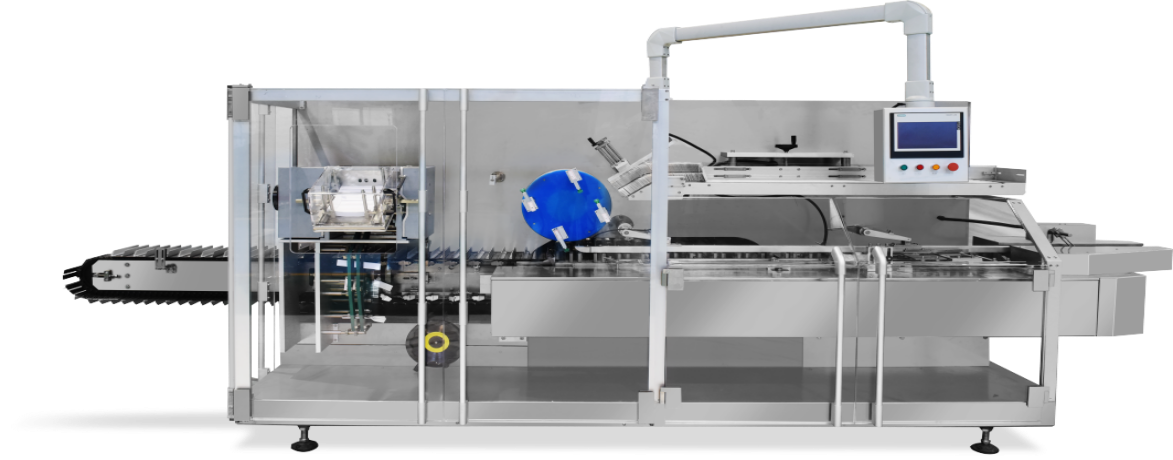

An all-in-one case packer is a type of automated packaging machine designed to combine several key functions into one integrated unit. Unlike traditional packaging systems, which require multiple machines for tasks like case forming, product loading, and sealing, these machines automate the entire process.

From product orientation to case forming and sealing, these machines help businesses automate the packaging process, reducing labor costs and improving speed.

Key Features of All-in-One Case Packers:

- Automated product loading and unloading

- Versatility in handling a wide range of product types

- Compact design for space-saving

- Ability to handle different case sizes and packaging formats

How Do All-in-One Case Packers Work?

The efficiency of an all-in-one case packer lies in its streamlined process. Here’s how it works:

- Product Orientation: The product enters the system and is oriented for accurate placement into the case.

- Case Forming: The machine automatically forms flat cardboard into a fully functional box.

- Product Loading: Once the case is formed, the machine uses automated mechanisms to load products efficiently into the box.

- ختم: After the box is filled, the system seals it securely, using either tape or glue, depending on the setup.

- Discharge: The packed case is discharged onto a conveyor belt, ready for shipment.

This efficient process combines several stages of packaging, cutting down on time, labor, and errors, making it ideal for high-volume production.

Benefits of All-in-One Case Packers

- Increased Efficiency

By consolidating multiple tasks into one machine, all-in-one case packers streamline your packaging process, reducing downtime and enhancing production speed. The result? Faster and more reliable product packing. - Cost Savings

Reducing reliance on manual labor and minimizing human error, these machines lower operational costs. Additionally, automated packaging systems are energy-efficient, further reducing overheads. - Improved Product Safety and Quality

Automated systems ensure products are packed correctly and securely, minimizing damage during handling. This is particularly important for industries like pharmaceuticals and food that require precise and safe packaging. - Space Efficiency

With their compact design, all-in-one case packers take up less space than traditional, multi-machine packaging systems. This helps businesses optimize their production floor and save valuable warehouse space. - Flexibility in Packaging

These machines can handle a wide variety of products, from bottles and cans to boxes and custom-shaped containers. Whether your products are large or small, an all-in-one case packer can adapt to your needs.

Industries That Benefit from All-in-One Case Packers

- Food and Beverage

From bottles to cans, automated packaging systems are critical for fast-moving consumer goods (FMCG) in the food and beverage industry. They improve speed and accuracy while maintaining product quality. - المستحضرات الصيدلانية

In the pharmaceutical sector, where precision is vital, all-in-one case packers help pack medications, bottles, and cartons securely. Their reliability ensures the safe transport of sensitive products. - Cosmetics and Personal Care

Cosmetic manufacturers can benefit from the gentle yet efficient operation of automated case packers, which protect delicate items like glass perfume bottles or jars of cream. - السلع الاستهلاكية

Whether you’re packing electronics, cleaning products, or toys, an all-in-one case packer offers flexibility and speed, reducing the time and labor required to pack consumer goods.

Choosing the Right All-in-One Case Packer for Your Business

When selecting an automated case packing machine, here are some factors to consider:

- نوع المنتج: Make sure the case packer is compatible with your specific products.

- Speed: Choose a machine that aligns with your production needs, ensuring it can handle your required output.

- Space: Consider the available space in your facility. Compact case packers are ideal for smaller production areas.

- Customization Options: Look for systems that allow easy configuration for different case sizes or product types.

Why All-in-One Case Packers Are Essential for Modern Packaging

All-in-one case packers are revolutionizing packaging operations by automating multiple tasks into one streamlined process. Offering benefits such as increased speed, reduced costs, and improved product quality, these machines are ideal for industries ranging from food and beverage to pharmaceuticals.

By adopting these automated systems, businesses can not only optimize their packaging workflows but also position themselves for long-term success. All-in-one case packers represent a forward-thinking approach to packaging, enabling businesses to meet growing demand while ensuring the integrity and safety of their products.